- Home

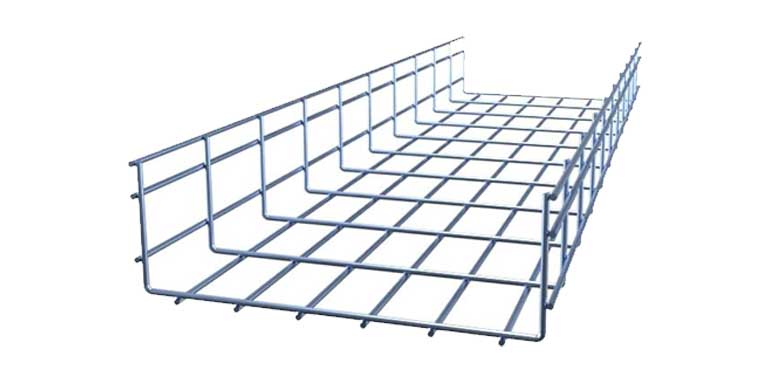

- Wire Mesh Cable Tray in India

Wire Mesh Cable Tray Manufacturers in India|Wire Mesh Cable Tray Manufacturers|Wire Mesh Cable Tray in India

Topmost Wire Mesh Cable Tray Manufacturers|Wire Mesh Cable Tray Manufacturers in India.Get Quality Wire Mesh Cable Tray in India as we are leading Wire Mesh Cable Tray Manufacturers| Pratik Cabletray Pvt. Ltd. We are Manufacturer, Supplier, Exporter of Wire Mesh Cable Tray, Pre Galvanized, Powder Coated Wire Mesh Cable Trays, Cable Tray Systems and our setup is situated in Pune, Maharashtra, India.

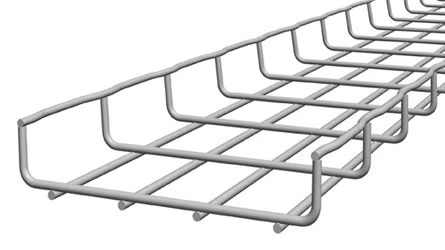

We are leading wire mesh cable tray manufacturers in India, suppliers, exporters of wire mesh cable tray in India by Pratik Cabletray Pvt. Ltd. As we are leading wire mesh cable tray manufacturers in India offering quality and reliable Wire Mesh Cable Tray in India Get Best Quote Now. Wire Mesh Cable Tray Manufacturers in India, Wire mesh Type Cable Tray Suppliers in India, Wire Mesh Cable Tray Exporters in India, Wire Basket Cable Tray Manufacturers, Wire Basket Cable Tray Manufacturers Exporters, and Wire Basket Cable Tray Suppliers, Wire Mesh Cable Tray in India, Stainless Steel Wire Mesh Cable Tray Suppliers, Galvanized Wire Mesh Cable Tray Manufacturers, Customized Cable Tray Solutions, Steel Wire Mesh Cable Tray Exporters, Wire Mesh Cable Tray Cross Manufacturers in India, Wire Mesh Cable Tray Tee Manufacturers in India, Horizontal Bend, Wire Mesh Cable Tray Vertical Inside Bend, Wire Mesh Cable Tray Vertical Outside Bend

Pratik Cabletray Pvt. Ltd. is the leading wire mesh cable tray manufacturers in India, as well as prominent wire mesh cable tray suppliers and exporters in India. We have integrated high-standard quality products with guaranteeing performance, durability, and reliability. You can trust solutions we deliver. Wire mesh cable trays are changing the face of cable management by offering a rigid, yet flex support system for planning and safeguarding your mission-critical network equipment.

Wire Mesh Cable Tray Manufacturers in India

With this wire mesh cable trays guide as your companion, enter the realm of wire mesh cable trays, to summarize briefly our general categories, self-explanatory benefits, general uses, and why and how these must be at the top of your priority list as the most productive, efficient, and future-proofed cable management system.

For businesses in India, connecting with top-rated Wire Mesh Cable Tray Suppliers in India ensures access to premium quality, timely delivery, and custom solutions that align with national standards. These trays should top your priority list due to their unmatched productivity, efficiency, and future-proof design, ideal for dynamic environments.

Why Choose our Wire Mesh Cable Tray Manufacturers?

Choosing wire mesh cable tray manufacturers in India offers a blend of quality, cost-efficiency, and innovation that makes them a smart choice for any project. Here's why:

- Streamlined Planning Effectively: Understands and keeps various cable forms as separate entities independently of one another without interference and tangling.

- Enhanced Safety: Facilitates to minimize trip risk and protect cables against wear and tear, resulting in a secure condition galvanised perforated cable tray.

- Future-Proof Flexibility: Enables to expand to accommodate cable path modification, upgrade, and addition with your business's expansion.

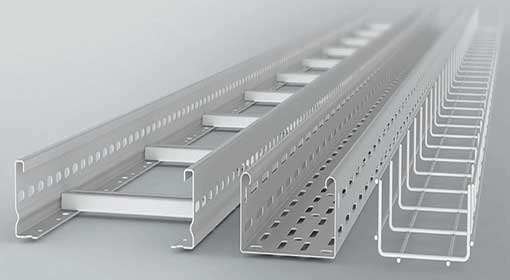

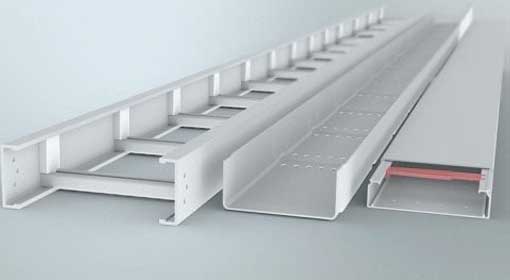

Types of Wire Mesh Cable Tray Manufacturing:

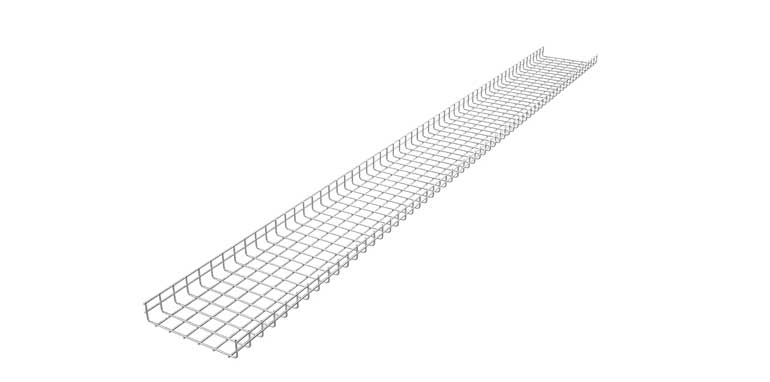

Being as wire mesh cable tray manufactures in India, different types as per availability and different bend size and section accordingly which are given below.

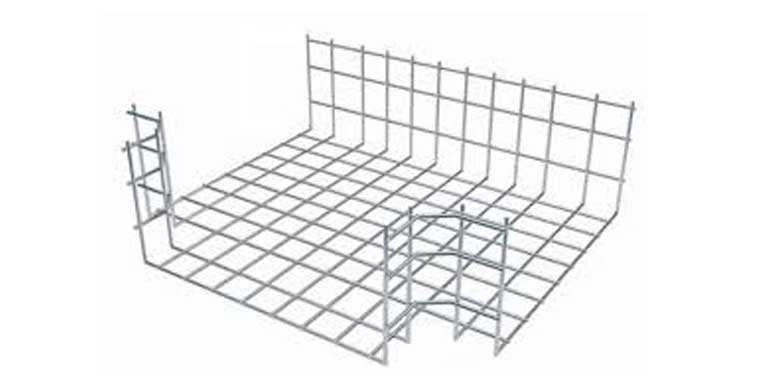

- Wire Mesh Cable Tray Cross: It is employed where four wire mesh cable tray runs are intersecting at a junction point to create a four-way intersection junction. It supports complex cable running in grid pattern or branching pattern.

- Wire Mesh Cable Tray Tee: box type cable tray manufacturer in India is tee fitting when there is an intersection of three wire mesh cable trays in a joint in the form of a T. It provides room for a center cable course to branch out into two diverse courses.

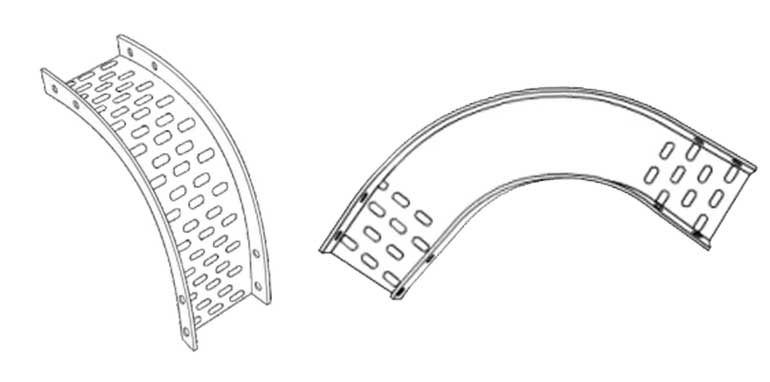

- Horizontal Bend: Horizontal bend is the kind which bends the wire mesh cable tray in a corresponding direction horizontally. It is available in more than one angle (e.g., 45°, 90°) to fit around obstructions or into the desired shape of installation.

- Wire Mesh Cable Tray Vertical Inside Bend: It is a fitting to lower the cable tray to a lower vertical plane and hence is a downward bend. The bend is "inside," or the intersection straight sections are at an acute angle.

- Wire Mesh Cable Tray Vertical Outside Bend: The reverse of the foregoing bend and has the effect of bending the wire mesh cable tray direction to the vertical plane with the formation of an upward bend. The outside is where the two parts joined at the ends forms an obtuse angle.

Technical Specification-Wire Mesh Cable Tray Manufacturers:

We have added below a technical sheet of wire mesh cable tray in India that provides more technical information such as:

| Specification Category | Specification Parameter | Typical Values/Options | Units | Key Considerations |

|---|---|---|---|---|

| Material & Finish | Material Grade | Carbon Steel (Q235, SS400), Pre-Galvanized Steel (PG), Hot-Dip Galvanized Steel (HDG), Stainless Steel (SS304, SS316, SS316L), Aluminum (6063-T6) | - | Consider the corrosive environment, mechanical strength requirements, and cost. Stainless steel offers the best corrosion |

| Wire Diameter | 3.5 mm, 4.0 mm, 4.5 mm, 5.0 mm, 5.5 mm, 6.0 mm | mm | Influences the load-bearing capacity and rigidity of the tray. Thicker wires provide higher strength. | |

| Mesh Size (WxL) | 50x50 mm, 50x100 mm, 50x150 mm, 100x100 mm | mm x mm | Affects cable ventilation, support frequency, and the ability to pass cables through the mesh. Smaller mesh sizes offer better support for smaller cables. | |

| Dimensions & Configuration | Width | 100 mm, 150 mm, 200 mm, 300 mm, 400 mm, 500 mm, 600 mm, 750 mm, 900 mm | mm | Determined by the number and size of cables to be installed. |

| Height (Depth) | 50 mm, 75 mm, 100 mm, 150 mm | mm | Influences the cable stacking capacity and the overall rigidity of the system. Higher depths allow for more cable layers. | |

| Standard Length | 3000 mm (3 meters), 6000 mm (6 meters) | mm | Affects installation speed and the number of joints required. | |

| Side Rail Configuration | Straight, Flared (EZ Bend) | - | Flared side rails simplify the creation of bends and transitions on-site, reducing the need for separate fittings. | |

| Bottom Wire Configuration | Transverse Welded, Longitudinal Welded | - | Impacts the cable support and the ease of cable installation and removal. Transverse welding generally provides better cable support. | |

| Performance & Load Capacity | Static Load Rating (UDL) | Varies significantly based on width, height, wire diameter, and support span (e.g., 50 kg/m to 200+ kg/m) | kg/m | The maximum weight the cable tray can support uniformly distributed between supports without permanent deformation exceeding a specified limit. This is a critical factor for safety and longevity. |

| Deflection Limit | Typically L/100, L/150, or L/200 (where L is the support span) | - | The maximum allowable vertical deflection of the tray under the static load. Lower values indicate less sag. | |

| Safety Factor | Typically 1.5 to 3.0 | - | A multiplier applied to the calculated maximum load to ensure the structural integrity of the cable tray system under various operating conditions and potential overloads. | |

| Installation & Accessories | Connection Methods | Bolt & Nut, Tool-less Couplers, (Welded Connections - less common for standard installation) | - | Tool-less couplers offer faster installation. Bolt and nut connections provide a robust and reliable joint. |

| Grounding/Earthing Provisions | Pre-punched grounding holes, integral grounding straps, provisions for grounding clamps | - | Essential for electrical safety. Ensure the cable tray system can be effectively grounded. | |

| Fittings & Accessories | Bends (Horizontal, Vertical - Inside/Outside), Tees, Crosses, Reducers, End Caps, Dividers, Cable Retainers, Support Brackets (Wall, Ceiling, Floor), Suspension Kits, Bonding Jumpers | - | A comprehensive range of fittings and accessories is crucial for creating complex cable routing pathways and ensuring proper cable management. | |

| Standards & Compliance | Industry Standards | IEC 61537 (Cable tray systems and cable ladder systems for electrical installations), NEMA VE 1 (Metal Cable Tray Systems), CSA C22.2 No. 126 (Cable Trays and Raceways) | - | Compliance with relevant international and regional standards ensures product quality, safety, and interoperability. Specify the required standards for your project. |

| Fire Rating | Optional - may specify requirements for fire propagation resistance (e.g., IEC 61537-3) | - | In specific applications, fire-rated cable tray systems may be necessary to prevent the spread of fire. | |

| Environmental Rating (IP) | Not typically an IP rating for the tray itself, but consider the environment when selecting material and finish. Enclosures mounted on the tray will have IP ratings. | - | The environment where the cable tray will be installed (e.g., indoor, outdoor, corrosive) dictates the appropriate material and finish. |

Benefits of Wire Mesh Cable Tray:

Serve as wire mesh cable tray suppliers in India, for maintenance, replacement and upgradation purpose different benefits are serve which are given below.

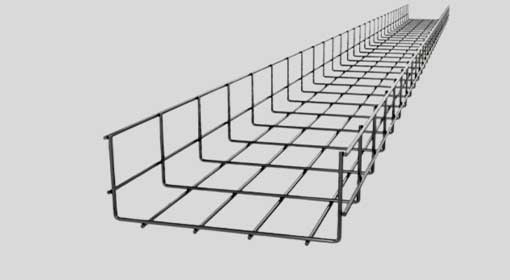

- Superb Ventilation: The mesh-through feature permits continuous airflow over the cables to prevent heat build-up and extend our lifespan. This is particularly useful in high temperatures or in cases of compact cable runs, reducing cable wear.

- Easy Installation: Simple bolt-together or snap-fit construction makes them simple and convenient to. Additionally, adjustments and modifications in cable runs can easily be made subsequently, and flexibility to adjust to future change can be established.

- Enhanced Accessibility: Open architecture provides quick visual access to the cables for inspection, maintenance, and fault tracing. Individual cables are found and accessed quickly for replacement or upgrade with much less time and intrusiveness compared to closed systems.

- Less Expensive: Wire mesh cable tray cross are less material and labor expensive to install than other traditional cable management devices such as ladder trays or conduits. The flexibility and versatility of wire mesh trays also reduce costs in the long run.

- Versatility and Flexibility: Wire mesh cable trays are supplied cut, molded, and installed on-site in a way to bend around complex routes and even obstructions. With such versatility, given the capability of accommodating adequate quantities of all forms of mounting spaces including use as individual cable guidance units.

Applications Wire Mesh Cable Tray:

As wire mesh cable tray exporters in India, it is applied in various industries and facilities area which are given below.

- Data Centers: Wire mesh trays suppliers in india are employed within networked data centers and power cable to ventilate, organize, and access necessary to enhance the maintenance and management of mission-critical infrastructure, reduce downtime, and maximize performance.

- Commercial Facades: From office buildings to shopping malls, wire mesh trays provide a stylish and discreet means of cleaning up suspended power, data, and communications cabling from ceilings or sweeping walls. These render ambient space safer and more beautiful.

- Industrial Equipment: These shield and channel power cables, control cables, and instrumentation wires by vigorous processes in plants and processing units. These facilitate unhindered movement of critical systems and equipment because can withstand effects over extended durations.

- Food and Beverage Industry: The exposed wire mesh tray design is not retaining dust and dirt, hence a hygienic cable management system for use where there are high-hygiene applications. This maintains sanitary conditions in our original state as well as prevents contamination too.

- Health Facilities: Hospitals and clinics rely on proper cable management of communications networks and medical equipment critical to medical treatment. Wire mesh cable trays can be readily supplied for easy upgrading and rapid maintenance without detracting.

Pratik Cabletray Pvt. Ltd. is the recommended wire mesh cable tray manufacturers in India, wire mesh cable trays have been one of the most sought-after cable management products of the era since these are cheap, budget-friendly, and with some practical benefits. The mesh exceeds most of the largest issues associated with standard solutions to provide more ventilation, access, and fit. Industrial buildings or data centers benefit from the flexibility to give them a pearl to possess in order to use for various types of purposes with efficient and unobstructed cable infrastructure in the long run. Get in touch with us.

Popular Searches of Wire Mesh Cable Tray Manufacturers:Wire Mesh Cable Tray Manufacturers in India, Wire mesh Type Cable Tray Suppliers in India, Wire Mesh Cable Tray Exporters in India, Wire Basket Cable Tray Manufacturers, Wire Basket Cable Tray Manufacturers Exporters, and Wire Basket Cable Tray Suppliers, Wire Mesh Cable Tray in India, Stainless Steel Wire Mesh Cable Tray Suppliers, Galvanized Wire Mesh Cable Tray Manufacturers, Customized Cable Tray Solutions, Steel Wire Mesh Cable Tray Exporters, Wire Mesh Cable Tray Cross Manufacturers in India, Wire Mesh Cable Tray Tee Manufacturers in India, Horizontal Bend, Wire Mesh Cable Tray Vertical Inside Bend, Wire Mesh Cable Tray Vertical Outside Bend

Wire Mesh Cable Tray Manufacturers in India

All Type of Wire Mesh Cable Trays in India

Wire Mesh Cable Tray Suppliers in India

Our Products

Cable Tray

We have carved a distinct niche in the market owing to the specialized skills, commitments and dedications or our workforce.

Read More

Perforated Type Cable Tray

We have carved a distinct niche in the market owing to the specialized skills, commitments and dedications or our workforce.

Read More

Ladder Type Cable Tray

We have carved a distinct niche in the market owing to the specialized skills, commitments and dedications or our workforce.

Read More

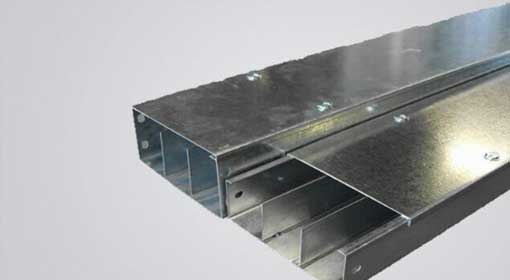

Box Type Cable Tray

We have carved a distinct niche in the market owing to the specialized skills, commitments and dedications or our workforce.

Read More

Wire Mesh Cable Tray

We have carved a distinct niche in the market owing to the specialized skills, commitments and dedications or our workforce.

Read More

FRP Cable Tray

We have carved a distinct niche in the market owing to the specialized skills, commitments and dedications or our workforce.

Read MoreFAQs on Wire Mesh Cable Trays:

These are generally constructed of steel, including pre-galvanized steel, hot-dip galvanized steel, and grades 304 and 316 stainless steel and, in certain applications, aluminum depending on the application and ambient conditions.

These are supported by a range of means such as center support hangers, floor supports, ceiling mounting, and wall mounting based on the mounting point and load.

Yes, through the use of materials with sufficient corrosion resistance, e.g., hot-dip galvanized or stainless steel, to match external weather conditions.