- Home

- Ladder Cable Tray in India

Top Best Ladder Cable Tray Manufacturers in India 2025|Leading Ladder Cable Tray Manufacturers-Pratik Cabletray

Top ladder cable tray manufacturers, ladder cable tray manufacturers from India | Pratik Cabletray Pvt. Ltd. Pune, MH, India. Manufacturers of GI Ladder Cable Tray, Galvanised Iron Ladder Cable Tray Manufacturers, Stainless Steel Ladder Cable Tray Manufacturers, Aluminium Ladder Cable Tray manufacturers Get a Quote Now for best ladder cable tray in India.

We are leading ladder cable tray manufacturers in India. suppliers, exporters of ladder cable tray in India. Find here high-performance and durable ladder cable tray from best ladder cable tray manufacturers in India. As we are Ladder Cable Tray Manufacturers In India we are offering GI Ladder Type Cable Tray Cross In India, Ladder Cable Tray Manufacturers, Galvanised Iron Ladder Cable Tray Manufacturers, Stainless Steel Ladder Cable Tray Manufacturers, Aluminium Ladder Cable Tray manufacturers, Ladder Cable Tray, Ladder Cable Tray Cross, Ladder Cable Tray In India, Steel Pre-Galvanized Painted Cable Tray manufacturers, GRP Ladder Type Cable Tray Manufacturers, Ladder Cable Trays in India.

Pratik Cabletray Pvt. Ltd. is the leading ladder cable tray manufacturers in India, as well as prominent ladder cable tray suppliers and exporters in India. With decades of industry experience, Pratik Cabletray Pvt. Ltd. has built a solid reputation for delivering high-performance, durable, and precisely engineered cable trays and accessories that meet the highest standards of safety and efficiency. Our products are designed to support power systems in various industrial and commercial application, helping clients streamline operations and minimize electrical hazards.

Ladder Cable Tray Manufacturers in India

From big manufacturing plants to sophisticated data centers, Cable trays from ladder are an affordable and simple solution. Let us proceed to the universal types, indefeasible benefits, and extensive applications that make them a part of the industrial era's integral commodity. Discover why it is best to take it as a smart move for utilizing Ladder Cable Trays suppliers in India for an economical and frugal operation.

Ladder Cable Tray in India

As one of the most trusted ladder cable tray suppliers in India and ladder cable tray expoters in India, we offer a comprehensive product range that includes straight lengths, horizontal bends, vertical elbows, tees, reducers, and supporting accessories — all designed to streamline cable routing while maximizing safety and operational efficiency.

Why Choose Our Ladder Cable Tray?

Ladder Cable Tray manufacturers in India and Ladder Cable Tray suppliers in India are an investment in a future-proof, long-term flexible cable management system. Open construction design makes it simpler to install and maintain, protect cables better, and ventilate. This means more safety, reduced downtime, and a neater, more effective process. Ladder Cable Trays are the option for long-term reliability and flexibility.

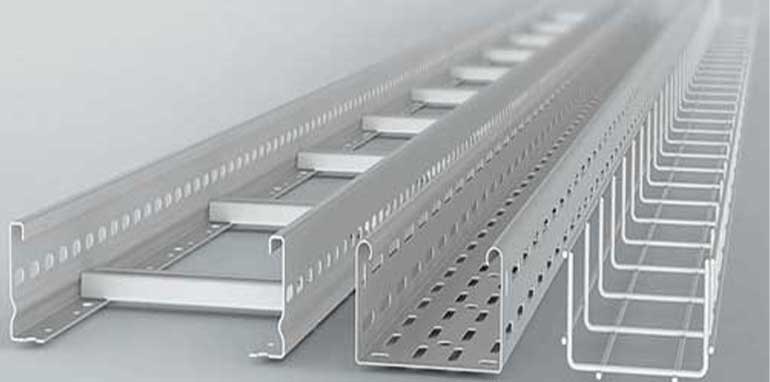

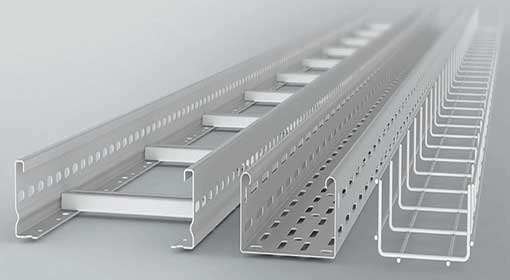

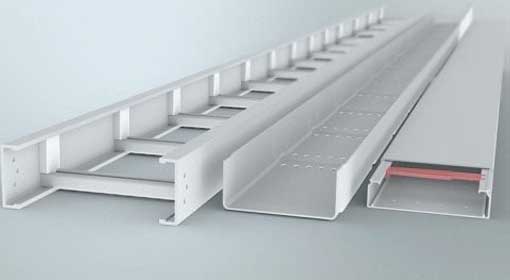

Types of Ladder Cable Tray:

Being as ladder cable tray manufacturers in India, as per different cable tray fittings types are modified which are given below.

- GI Ladder Cable Tray: Galvanized iron consisting of side rails and rungs with robust support and proper ventilation for high-duty industrial cable runs. GI perforated cable tray manufacturer ladder style enables easy access to cables and management of cables.

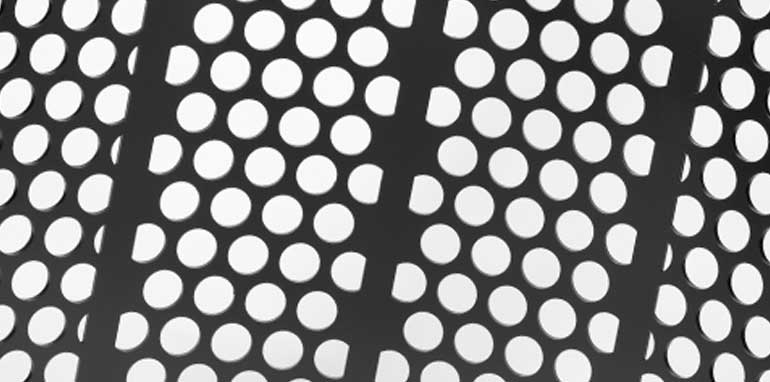

- Perforated Cable Tray: Bottom vented trays with holes on the bottom and sides. This is the best choice for storage of a large number of types of cables, which are widely used in light industrial and commercial setups.

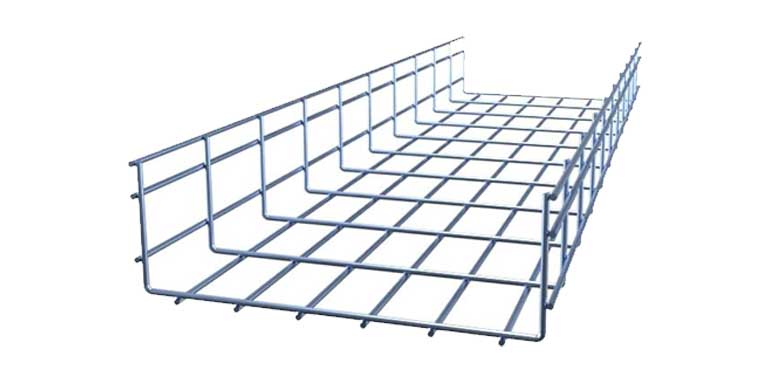

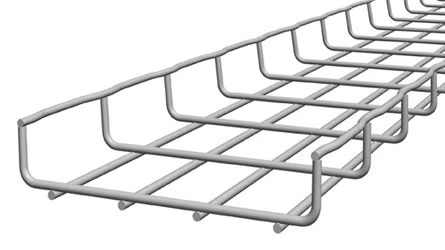

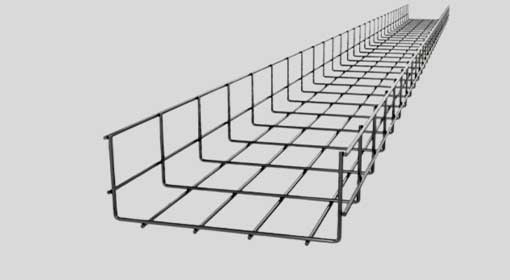

- Cable Baskets:: Wire basket trays are also referred to as wire mesh trays. These are made of welded steel wires in mesh form. These are fully ventilated and offer flexibility for cable runs and are mainly used in data centers and IT rooms.

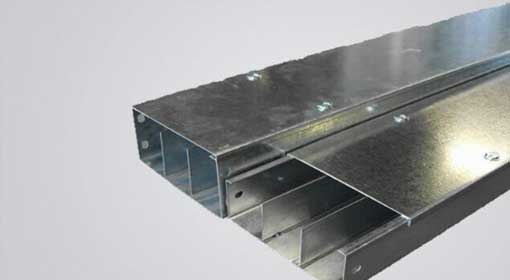

- Box Type Cable Tray: Sides and bottoms of solid trays, junction boxes usually covered up, and which are optimum for protection against physical damage and dust, usually used for critical cables or where conditions are at a critical level.

- Wire Mesh Cable Tray: As ladder cable tray manufacturers in India, same as it is a synonym of cable tray accessories. These are made up of welded wire steel in a basket cable tray shape, which is highly suitable for airflow and flexibility.

- Pipe and Instrumentation fitting: Cable tray pipe and instrumentation fittings are unique fittings used to connect cables and piping systems into a cable tray system. The fittings consist of brackets, clamps, and supports that secure pipes, tubing, and instrumentation cables.

Technical Specification of Manufacturing Ladder Cable Tray :

We have added below a technical sheet of ladder cable tray in India that provides more technical information such as:

| Feature | Specification Range | Units | Notes |

|---|---|---|---|

| Material | Mild Steel (MS), Pre-Galvanized Steel (PG), Hot-Dip Galvanized Steel (HDG), Stainless Steel (SS304, SS316, SS316L), Aluminum Alloy | - | Material selection depends on the environment and corrosion resistance requirements. |

| Finish | Plain, Powder Coated (various colors), Epoxy Coated | - | Coating provides additional protection against corrosion and can be customized for specific environments. |

| Width (W) | 50 mm to 1500 mm (or more, depending on the manufacturer) | mm | Determines the cable carrying capacity of the tray. Common widths include 150mm, 300mm, 450mm, 600mm. |

| Height/Depth (H) | 25 mm to 150 mm | mm | Influences the number of cable layers that can be accommodated. Common heights include 50mm, 75mm, 100mm, 150mm. |

| Thickness (T) | 1.2 mm to 3.0 mm (or more) | mm | Affects the load-bearing capacity and rigidity of the cable tray. |

| Length (L) | Standard lengths: 2.4 m, 3 m, 6 m (custom lengths available) | m | Length of individual sections of the cable tray. |

| Rung Spacing (RS) | 150 mm to 300 mm (standard) | mm | Distance between the rungs, which support the cables. Closer spacing provides better support for smaller cables. |

| Rung Type | Perforated, Solid, Tubular | - | Perforated rungs allow for cable tie-down and ventilation. Solid rungs provide continuous support. Tubular rungs offer high strength. |

| Side Rail Configuration | C-Channel, I-Beam, Z-Section | - | Design of the side rails impacts the strength and mounting options. |

| Load Capacity (Uniformly Distributed Load - UDL) | Varies significantly (e.g., 30 kg/m to 250 kg/m or more) | kg/m | Maximum weight the cable tray can safely support per unit length, depending on material, thickness, and design. |

| Support Span | 1.5 m to 6 m (recommended maximum) | m | Maximum distance between supports while maintaining the specified load capacity. |

| Operating Temperature | -50°C to +150°C (depending on material and finish) | °C | Temperature range within which the cable tray can function without degradation. |

| Standards Compliance | IEC 61537, NEMA VE 1, UL 870, IS 2629/4759, BS EN 10346, ASTM A123/A123M (depending on region and application) | - | Indicates adherence to recognized industry standards for safety, performance, and quality. |

Benefits of Ladder Cable Tray:

Serve as ladder cable tray suppliers in India, different benefits are there as per system and production purposes which has given below.

- Greater Cable Protection: Strength and sturdiness of ladder cable tray design and construction provide greater physical protection from environmental exposure, impact, and abrasion, with greater reliability and raceways cable trays life for the cabling system.

- Greater Ventilation: Open rung design allows for greater ventilation space around cables. Heat entrapment is eliminated, which reduces cable insulation, leading to performance issues, producing an efficient and safer system.

- Easy Repair and Installation: Open architecture provides direct access to mounting points and cable runs without obstruction. This permits easy conversion of original installation into easy observation and makes easy simple future addition possible with cost-saving systems.

- High Load-Bearing Capacity: ladder Cable tray expoters in India are designed to support high cable loads over long spans. Wiremesh type cable tray supplier is therefore ideal for application in heavy cables in high density to provide structural support without sagging.

- Flexibility and Versatility: Since cable trays come in different types of materials, sizes, and arrangements, there is the possibility of designing it to fit most industrial requirements and project applications, and hence it can be a flexible cable management system.

Applications of Ladder Cable Tray

As ladder cable tray exporters in India, ladder cable tray suppliers in India, as per different sectors, centers and infrastructures need it is applied which are given below.

- Factory Plants: Commonly employed in cabling and cabling of running cables to power and control the plant machinery and equipment. These provide a methodical and systematic means of fulfilling the stupendous wiring requirement of factory production and automated lines.

- Power Generation and Distribution: Needed in supply of high voltage power cables of power houses and substations. Our robust structure allows secure transmission of electricity and systematic presentation, as required by good power infrastructure.

- Oil and Gas Sector: Applied to onshore and offshore equipment in order to insulate instrumentation, control, and power cables against abrasive and unforgiving surroundings. Anti-corrosive metal like aluminum or specialty paints are the greatest material for longer application.

- Telecommunication and Data Centers: Utilized to cover and encase the vast web of data and telecommunications cables. Ladder Cable tray Manufacturers in India with our open style, airflow finds its welcome for preventing excessive overheating of delicate equipment and maximum performance.

- Commercial Buildings and Infrastructure: Used in big business centers, airports, traffic infrastructure for management of electrical cables, communication cables, and security cables system, clean and secure delivery system.

Pratik Cabletray Pvt. Ltd. is the recommended ladder cable tray manufacturers in India and ladder cable tray manufacturers in India are one of the highest performing and most utilized cable management systems used in industry. Our durability, accessibility, and ventilation provide them with very high utilization in cable protection, system maintenance, and overall working efficiency. With companies relying on more advanced cable systems increasingly, the function of Ladder Cable Trays in keeping everything organized, safe, and efficient as much as providing power and data is even more unmatched. Contact us for more details.

Related Seraches of ladder cable tray: Ladder Cable Tray Manufacturers In India, Ladder Cable Tray Suppliers In India, Ladder Cable Tray Exporters In India, GI Ladder Type Cable Tray Cross In India, Ladder Cable Tray Manufacturers, Ladder Cable Tray Suppliers, Ladder Cable Tray Exporters, GI Ladder Cable Tray In India, GI Ladder Cable Tray Manufacturers In India, GI Ladder Cable Tray Suppliers In India, And GI Ladder Cable Tray Exporters In India, Galvanised Iron Ladder Cable Tray Manufacturers, Stainless Steel Ladder Cable Tray, Aluminium Ladder Cable Tray, Ladder Cable Tray, Ladder Cable Tray Cross, Ladder Cable Tray In India, Steel Pre-Galvanized Painted Cable Tray, GRP Ladder Type Cable Tray, Ladder Cable Trays

Ladder Cable Tray Manufacturers in India

All Type of Ladder Cable Trays in India

Ladder Cable Tray Suppliers in India

Our Products

Cable Tray

We have carved a distinct niche in the market owing to the specialized skills, commitments and dedications or our workforce.

Read More

Perforated Type Cable Tray

We have carved a distinct niche in the market owing to the specialized skills, commitments and dedications or our workforce.

Read More

Ladder Type Cable Tray

We have carved a distinct niche in the market owing to the specialized skills, commitments and dedications or our workforce.

Read More

Box Type Cable Tray

We have carved a distinct niche in the market owing to the specialized skills, commitments and dedications or our workforce.

Read More

Wire Mesh Cable Tray

We have carved a distinct niche in the market owing to the specialized skills, commitments and dedications or our workforce.

Read More

FRP Cable Tray

We have carved a distinct niche in the market owing to the specialized skills, commitments and dedications or our workforce.

Read MoreFAQs regarding Ladder Cable Tray

Cables are normally secured by cable ties, clips, or cable-specific fasteners that attach onto the rungs of the ladder tray, retaining and keeping them organized.

Cables to be housed in number and size, ventilation gap between cables, and future expansion of cables are important factors.

Yes, ladder cable trays can be used outdoors if the finish and material are chosen to provide good weathering and corrosion protection, e.g., hot-dip galvanized steel or aluminum.