- Home

- GI Foundation Bolt Manufacturer

GI Foundation Bolt Manufacturers in India - Pratik Cabletray Pvt. Ltd.

Pratik Cabletray Pvt. Ltd. is the leading GI foundation bolt manufacturers in India, as well as prominent GI foundation bolt suppliers and exporters in India. All industry solution is our cable management solutions to all industry verticals, from manufacturing to construction. Our solutions are tailor-made to your very own needs, so we've got you covered.

Our expertise goes far beyond bolts — we specialize in comprehensive cable management solutions tailored for a wide range of industry verticals, including manufacturing, construction, infrastructure, energy, and more. Whether you’re building from the ground up or upgrading an existing setup, our robust product lineup and expert support ensure seamless performance and long-lasting reliability.

GI Foundation Bolt Suppliers in India

GI foundation bolts are the workhorses, providing anchor-like strength and support that resists. These support an enormous load, placing buildings in position and fighting colossal forces. The selection of a best foundation bolt makes a significant difference to safety, strength, and success in all industrial construction. Let's have a look into the world of GI foundation bolts, typical kinds, greatest benefits, wide utilization, and reasons why these prove to be best choice for an unshakeable and robust base.

Why to Choose GI Foundation Bolt?

Opt for GI foundation bolts for complete resistance against corrosion in order to offer long life under tough conditions. These are high strength to maintain structure integrity as well as secure safe anchorage of heavy weights. Using GI reduces maintenance and replacement costs over a long term. Finally, these give one peace of mind with the promise of improved safety and reliability in your mission-critical industrial operation.

Types of GI Foundation Bolt:

Being as GI foundation bolt manufacturers in India, as per shape and suitable application need types are modified which are given below.

- L-Shaped Anchor Bolt: L-bent head bolts and are green concrete cast before hardening, to give greater pull-out resistance because of mechanical interlock because of setting of surrounding concrete in bent zone.

- J-Shaped Anchor Bolt: These are equivalent to L-bolts and made up of a J-shape curved anchor section to be seated in concrete. With an added benefit, the shape provides stiff mechanical keying, thus making it easier for them the possible use where there is a need of medium or high pull-out strength.

- Straight Anchor Bolts with Plate Washers: These are a plain rod with the threaded end and typically with a plate washer and nut. The plate washer provides more bearing area, distributing the load to a larger area of concrete and thereby providing more pull-out resistance.

- Sleeve Anchor Bolt: Equipped with nut, sleeve, and bolt, the anchors spring open when one tightens up the nut, developing good frictional grip within a pre-drilled concrete hole. Simple installation with them and suitable application wherever post-installed anchoring.

- Wedge Anchor Bolt: Wedge expansion mechanical anchors incorporate a wedge clip, which wedges over the sides of a masonry or concrete drilled hole as a bolt is tightened. These perform quite effectively to hold and are used most frequently in heavy-duty applications.

Technical Specification of GI Foundation Bolt:

We have added below a technical sheet of GI foundation bolt in India that provides more technical information such as:

| Specification | Detail | Common Values/Ranges |

|---|---|---|

| Material Grade | Specifies the strength and quality of the steel used before galvanization. Common grades include mild steel (IS 2062, ASTM A36), medium carbon steel (EN8, EN19), etc. | Mild Steel: Grade 4.6 (Common structural applications) |

| Medium Carbon Steel: Grade 5.6, 8.8 (Higher strength requirements) | ||

| Diameter (Nominal) | The diameter of the bolt's threaded portion. | Commonly ranges from M12 to M100 (metric) and 1/2" to 4" (imperial). Specific project requirements dictate the diameter. |

| Length (Overall) | The total length of the bolt, including the bend or any unthreaded portion. | Varies widely based on the application and embedment depth required. Can range from 100 mm to 3000 mm or more. Specified in project drawings. |

| Thread Length | The length of the threaded portion of the bolt. | Designed to accommodate the nut and any washers, and ensure sufficient grip. Typically 1.5 to 3 times the bolt diameter, but can be customized. |

| Bend Length (for J & L) | The length of the bent portion of J and L bolts. | Standard bend lengths are often 75 mm, 100 mm, 150 mm, but can be specified based on design needs to ensure adequate embedment and pull-out resistance. |

| Hot Dip Galvanization (HDG) | The process of coating the steel bolt with a layer of zinc by immersing it in molten zinc, providing superior corrosion protection. | Coating Thickness: Typically specified according to ASTM A153 or equivalent standards, with minimum average coating thicknesses ranging from 43 µm to 86 µm depending on the bolt size. |

| Adherence Test: The galvanization should adhere firmly to the steel base without flaking or peeling. | ||

| Thread Type/Standard | The form and pitch of the threads on the bolt. | Metric Coarse (ISO 68-1, ISO 965): Most common in many industrial applications. |

| BSW (British Standard Whitworth): Older standard, still found in some applications. | ||

| UNC/UNF (Unified National Coarse/Fine): Primarily used in North America. | ||

| Nut and Washer | Typically supplied with compatible GI nuts and washers. | Nut Grade: Should match or exceed the bolt grade (e.g., Grade 4, 5, 8 for metric; Class 2H for imperial). Commonly hexagonal (IS 1363, ASTM A563). |

| Washer Type: Plain washers (IS 2016, ASTM F436) are common to distribute load. Spring washers might be used for vibration resistance. Both should be GI coated. | ||

| Tolerance | Acceptable variation in bolt dimensions (diameter, length, thread pitch, etc.). | Generally specified according to relevant standards (e.g., ISO 4759-1 for bolts, ISO 4759-2 for nuts, ISO 4759-3 for washers). Standard tolerances (e.g., Class C) are typical, but tighter tolerances can be specified for precision applications. |

| Tensile Strength | The maximum tension stress the bolt can withstand before fracturing. | Determined by the material grade and bolt diameter. For example, a Grade 4.6 bolt has a minimum tensile strength of 400 MPa. |

| Yield Strength | The stress at which the bolt begins to deform plastically. | Also determined by the material grade. A Grade 4.6 bolt has a minimum yield strength of 240 MPa. |

| Embedment Depth | The depth to which the bolt must be embedded in the concrete to achieve the required holding capacity. | Calculated based on load requirements, concrete strength, and bolt geometry. Typically specified in engineering drawings and should adhere to relevant building codes and standards (e.g., ACI 318). |

| Pull-Out Resistance | The maximum force the embedded bolt can withstand before being pulled out of the concrete. | Depends on embedment depth, concrete strength, bolt shape, and any additional anchoring mechanisms (e.g., plate washers). Design values are crucial for structural integrity. |

| Shear Resistance | The maximum force the bolt can withstand perpendicular to its axis. | Important for applications where lateral loads are expected. Depends on bolt diameter and material strength. |

| Packaging | How the bolts are typically packaged for transportation and storage. | Commonly packed in jute gunny bags, plastic packets, or wooden crates, depending on the quantity and size. Weight per pack can vary (e.g., 50 kg, 100 kg). |

Benefits of GI Foundation Bolt:

Serve as GI foundation bolt suppliers in India, it provides various of benefits which are resistant and suitable for environment as follow.

- Corrosion Resistance: Galvanizing treatment imparts a protective layer of zinc over the steel, which makes GI foundation bolts extremely corrosion- and rust-proof. This boosts life markedly, particularly when exposed to atmosphere or wet industries, minimizing replacement and maintenance costs.

- Long Life and High Strength: Made of long-lasting steel and solidly fixed in concrete, GI foundation bolts possess high tensile strength and bearing capacity. These can withstand heavy loads and vibrations and can transfer stability and security to the building or machine.

- Economy: Although more costly to buy than non-galvanized ones, the long life and minimal maintenance of GI foundation bolts are economical in the long run. These save labor and time in the sense that these need not be replaced repeatedly.

- Improved Safety: By providing a tight and stiff connection between foundation and structure, GI foundation bolts greatly improve overall safety. Being corrosion resistant and high strength, these provide an impossible-to-burst yet extremely strong connection.

- Variety of Uses: GI foundation bolts vary in size and shape, and therefore these have immensely varying industrial uses, ranging from the anchoring of heavy machinery and building steel to mounting equipment and support systems in varying environments.

Applications of GI Foundation Bolt:

As GI foundation bolt exporters in India, it is applied in different plant, system and many more which are given below.

- Heavy Equipment Safety: Factories and factories utilize GI foundation bolts to fasten heavy equipment such as presses, generators, and turbines firmly into concrete floors. These are not able to shift, these eradicate vibration, and offer stable and even safety when used.

- Structural Steel Construction: In the construction of steel structures such as steel buildings, warehouses, and bridges, GI foundation bolts are utilized in joining the columns and steel base plates to the concrete foundation.

- Infrastructure Projects: GI foundation bolts are applied in every kind of infrastructure projects like repairing highway's light poles, sign boards, and road barriers or public property. These must be corrosion-resistant when these are installed outdoors.

- Anchoring Devices in Chemical Plants: In chemical process plants and other corrosive atmospheres, greater corrosion resistance of GI foundation bolts is needed to anchor tanks, pipes, etc., on concrete supports for safe operation for a long duration.

- Securing Support System: GI foundation bolts are used in order to protect an important amount of support systems such as cable trays, air ducts, and pipe clips from factory, commercial building ceilings, floors, and walls, and thus stabilize.

Pratik Cabletray Pvt. Ltd. is the recommended GI foundation bolt manufacturers in India. GI foundation bolts are a vital material employed in a very broad variety of industrial and building applications. Our inherent toughness, supplemented by protection in the guise of galvanization, offers durability, safety, and value for generations. From supporting huge machinery to giving stability to skyscrapers, these robust fasteners are the behind-the-scenes workers who are the backbone of industrial construction's reliability and integrity. Accurate selection of GI foundation bolt size and type is an extremely important decision that has a direct bearing on the success and safety of any operation.

Our Products

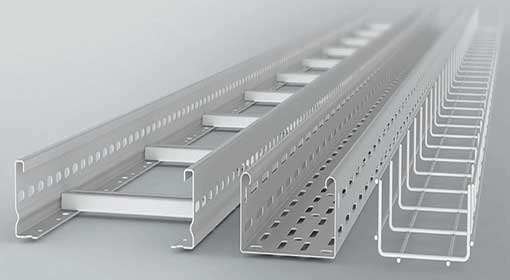

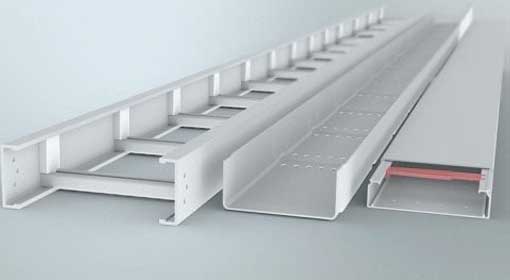

Cable Tray

We have carved a distinct niche in the market owing to the specialized skills, commitments and dedications or our workforce.

Read More

Perforated Type Cable Tray

We have carved a distinct niche in the market owing to the specialized skills, commitments and dedications or our workforce.

Read More

Ladder Type Cable Tray

We have carved a distinct niche in the market owing to the specialized skills, commitments and dedications or our workforce.

Read More

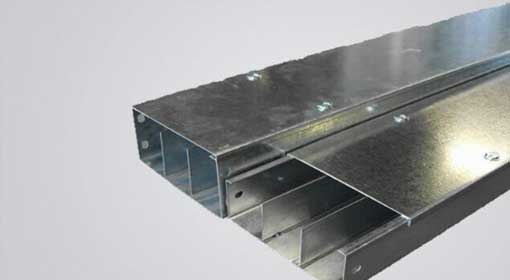

Box Type Cable Tray

We have carved a distinct niche in the market owing to the specialized skills, commitments and dedications or our workforce.

Read More

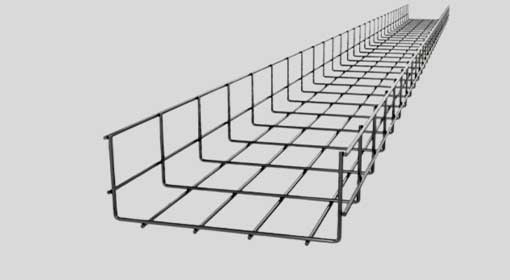

Wire Mesh Cable Tray

We have carved a distinct niche in the market owing to the specialized skills, commitments and dedications or our workforce.

Read More

FRP Cable Tray

We have carved a distinct niche in the market owing to the specialized skills, commitments and dedications or our workforce.

Read MoreFAQs on GI Foundation Bolts:

The primary function is to ensure that any explosion within the box is contained so that transmission of hot gases or flames to the outside explosive environment is avoided.

Flameproof junction boxes are tested by reputable test facilities and marked with certain explosion-proof ratings (e.g., Ex d) to reflect compliance with relevant safety standards.

No, standard junction boxes are not explosion-proof and should not be put where there can be explosive atmospheres. Certified flameproof or explosion-proof enclosures alone need to be installed.