- Home

- Perforated Cable Tray in India

Top Best Perforated Cable Tray Manufacturers in India 2025|Leading Perforated Cable Tray Manufacturers-Pratik Cabletray

Topmost Perforated Cable Tray Manufacturers|Perforated Cable Tray Manufacturers in India.Get Quality Perforated Cable Tray in India as we are leading Perforated Cable Tray Manufacturers. Powder Coated Perforated Cable Tray Manufacturers| Pratik Cabletray Pvt. Ltd.Pune MH India.

We are leading Perforated Cable Tray Manufacturers and Suppliers & Exporters of Perforated Cable Tray in India. As we are leading Perforated Cable Tray Manufacturers offering Perforated Cable Tray in India, GI Perforated Cable Tray Manufacturer, Perforated Cable Trays, GI Perforated Cable Tray Suppliers, GI Perforated Cable Tray Exporters, Aluminium Perforated Cable Tray, Galvanised Iron Perforated Cable Tray, Stainless Steel Perforated Cable Tray In India, Perforated Cross, Top SS Cable Tray Manufacturer in India, Powder Coated Perforated Cable Trays, Stainless Steel Cable Trays, Perforated Horizontal Bend in India.

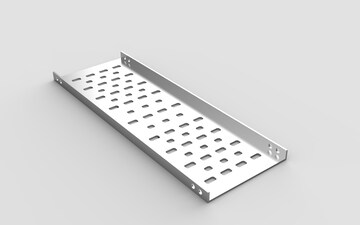

Pratik Cabletray Pvt. Ltd. is the leading perforated cable tray manufacturers in India, as well as prominent perforated cable tray suppliers and exporters in India. It is the backbone of tidy and organized cable management. Because these are tough and rugged in build, such systems provide a balanced and versatile cable way and cable support system for electric cables, instrumentation cables, and communication cables.

Made from high-grade materials such as galvanized iron (GI), stainless steel, and mild steel, our perforated cable tray suppliers in India are resistant to corrosion, wear, and harsh environmental conditions, making them ideal for long-term use in indoor as well as outdoor installations. The perforated design not only reduces weight but also allows for effective air circulation around the cables, which helps in dissipating heat and maintaining system performance.

Perforated Cable Tray Manufacturers: Efficient Cable Management Solutions

As Perforated Cable Tray Suppliers in India With all the various types and applications, then how do you ever actually go about selecting the very best one to use on your applications lie this? Segment the requirements, working down highest levels, primary benefits, usual applications, and why you'll be perfect with perforated cable trays manufacturers in India because buckle down and streamline procedures that little bit quicker and provide long term protection and safety on your all-important cabling installation.

Why Perforated Cable Tray?

Perforated cable trays are cost-effective and efficient cabling management system for many commercial and industrial applications. Perforations cause systematic flow, design ventilation achievable, maintenance simple, and expansion of your cabling system to its lifespan. There are types of perforated cable tray exporters in India that can be bought as per load bearing and climatic requirements needed, cost-effective investment in repetitive business process. Buying perforated cable trays in India is buying efficiency, safety, and cable future-proofing.

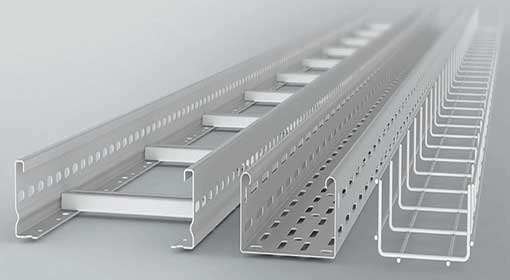

Types of Perforated Cable Tray:

Being as perforated cable tray manufacturers in India, different types are modified as per different shapes and need which are given below.

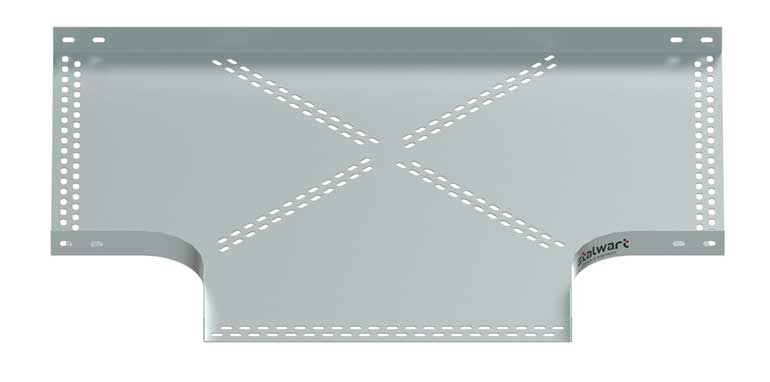

- Perforated Cross: Four-arm branch connector in which the cables meet at a point. Ventilation holes on both sides and cable hold-down points at various locations as cables go in various directions. Used in intricate cable routing design where there are many branches.

- Perforated Tee: T-interconnect to facilitate a cable run to fork in one direction from a trunk run. Similar to the cross, points of air flow and cable control with a hole and somewhere to connect to when forking 90 degrees.

- Perforated Horizontal Bend: It gives a neat 90-degree direction change in a horizontal cable run. Venting and tie points are allowed through perforation in the bend to keep cables neat and prevent stiff bends that may damage cables.

- Perforated Vertical Inside Bend: Used solely for bending the cable tray down by 90 degrees of height direction. Inner perforations as well as outer both offer ventilation and help decide where the cables are to be inserted while changing from one lower height but bend radius under our care.

- Perforated Vertical Outside Bend: It is a device that provides vertical height shift in cable trays up to 90 degrees. Air space for ventilation is provided through perforations for air passage as well as acts as points of cable control since the cables are directed.

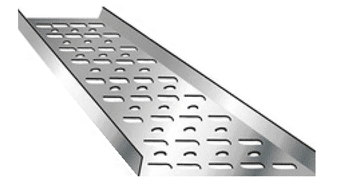

- Galvanized Iron (GI) perforated cable tray: GI perforated cable trays manufacturers in India are widely used in a variety of industrial applications and locations due to their high durability and corrosion resistance.

- Stainless steel (SS) perforated cable tray: It is perfect for demanding installations since they are designed for hard and corrosive environments and have a high resistance to corrosion, water, and chemical exposure.

- Aluminum perforated cable tray: Ideal for situations requiring a reduction in total weight load because they are lightweight and have outstanding corrosion resistance.

- Plastic Perforated Cable Tray: Plastic cable tray suppliers in India is suitable for applications where chemicals are a significant issue since they are highly resistant to corrosion.

Technical Specification of Perforated Cable Tray:

We have added below a technical sheet of perforated cable tray in India that provides more technical information such as:

| Feature | Specification Range/Options | Units | Notes |

|---|---|---|---|

| Material | Steel (Pre-Galvanized, Hot-Dip Galvanized after Fabrication - HDGAF, Stainless Steel (SS304, SS316), Aluminum (Various Alloys)), Fiber Reinforced Plastic (FRP) | Material selection depends on environmental conditions (corrosion resistance), load requirements, and cost. HDGAF offers superior corrosion protection. | |

| Thickness | Steel: 1.2 mm - 3.0 mm (Higher thicknesses available for heavy-duty applications), Aluminum: 2.0 mm - 5.0 mm, FRP: Variable depending on design | mm | Thickness affects the load-bearing capacity and rigidity of the tray. |

| Width | 50 mm - 1500 mm (Standard widths: 150, 300, 450, 600, 900 mm) | mm | Width is selected based on the number and size of cables to be supported. |

| Depth (Side Rail Height) | 50 mm - 150 mm (Standard depths: 50, 75, 100, 150 mm) | mm | Depth determines the cable stacking height and overall cable management capacity. |

| Length | Typically 2.4 m or 3.0 m (Custom lengths available upon request) | m | Standard lengths facilitate easier installation and transportation. |

| Perforation Pattern | Round holes (various diameters and spacing), Oblong holes, Square holes, Slotted holes (Standard and Custom patterns available) | Perforations provide ventilation for cables, allow for cable dropouts, and can aid in reducing cable weight. Pattern and spacing influence ventilation and structural integrity. | |

| Flange Type | Return flange (C-shape), Inward flange, Outward flange, No flange (Ladder type with perforated bottom) | Flange design impacts the tray's strength and the method of joining sections and accessories. Return flanges are common for added rigidity. | |

| Joining Methods | Bolted connections (using splice plates and hardware), Clamping systems (various designs for quick installation), Welding (primarily for custom fabrications or specific material types) | The joining method affects installation time and the structural integrity of the cable tray run. Bolted connections are the most common and versatile. | |

| Load Bearing Capacity | Uniform Distributed Load (UDL) rating specified in kN/m or kg/m (Varies significantly based on material, thickness, width, depth, and support span. Typically ranges from 0.5 kN/m to 5.0 kN/m or higher for heavy-duty applications) | kN/m, kg/m | Load bearing capacity is crucial for ensuring the tray can safely support the weight of the cables. Manufacturers provide load charts for different configurations. |

| Support Span | Typically 1.5 m - 3.0 m (Can be shorter or longer depending on load requirements and tray design) | m | The distance between supports significantly impacts the load-bearing capacity. Refer to manufacturer's guidelines for appropriate support spacing. |

| Standards Compliance | IEC 61537 (Cable tray systems and cable ladder systems), NEMA VE 1 (Metal Cable Tray Systems), CSA C22.2 No. 126 (Cable Trays and Cablebus), Other regional standards as applicable (e.g., UL) | Compliance with relevant industry standards ensures safety and performance. | |

| Earthing/Bonding Provisions | Pre-punched holes for grounding lugs, Integrated grounding channels or provisions for bonding jumpers | Proper earthing and bonding are essential for safety in electrical installations. | |

| Fire Performance (for FRP) | Flame retardant ratings (e.g., UL 94 V-0), Low smoke and fume properties | Important for safety in areas with fire hazards. FRP cable trays can be engineered with specific fire performance characteristics. |

Benefits of Perforated Cable Tray:

Serve as perforated cable tray suppliers in India and perforated cable tray exporters in India, different benefits are provided for improvement and upgrading affordability which are given below.

- Improved Cable Management: Perforated trays are a methodical cable way, which holds the cables in knotted style and prevents wasteful cable randomness, facilitates identification and handling of cables with ease, saves time and energy.

- Improved Ventilation and Heat Dissipation: Perforations create additional air space above the cables, thus preventing cable over-heating and extending cable life, which is very vital to get the system fully operational and safe.

- Easy Installation and Upgrading: Perforated Cable tray accessories suppliers in India modularity and free accessibility of perforations for fixing and fastening to enable easy installation and easy later addition or upgrading thereto.

- Improved Safety: Where cables are properly organized and neatly maintained, cable tripping hazards and cable body injuries are minimized to establish a safe working environment.

- Affordable Solution: Perforated cable trays suppliers in India provide an affordable solution to closed conduit systems and are better in terms of functionality, particularly where there are heavy installations.

Applications of Perforated Cable Tray:

Being as perforated cable tray exporters in India, as in different sectors of industry it is applied which are given below.

- Industrial Factories and Factory Plants: Used extensively for the deployment of power, control, and instrumentation cables to be used within the plant for neat and secure distribution to machinery and equipment.

- Commercial Building and Data Centers: Installed to transport network cable, IT power cable, and communications cable to provide an expandable and flexible system to accommodate growing technology needs.

- Power Generation and Distribution: Applied to power generation and substation buildings to facilitate handling high-voltage cabling and control wiring, to provide a strong and ventilated system for mission-critical power distribution.

- Transportation Infrastructure (Railways, Airports): Applied for cable housing of telecommunication and signaling cables, power transmission over transportation infrastructure in a safe and reliable way.

- Oil and Gas Industry: perforated cable tray manufacturer in India used on mounted onshore and offshore platforms for cable guidance of all types in hostile environments where these have to be rugged, corrosion-free cable management systems.

Pratik Cabletray Pvt. Ltd. is the recommended perforated cable tray manufacturers in India, suppliers and exporters in India, our perforated design maintains ventilation, ease of maintenance, and future expansion space. With our availability in various types to meet individual routing requirements and providing advantages such as enhanced safety and easy installation, perforated cable trays prove to be a convenient option for effective long-term cable protection. These are extensively used in industrial facilities, commercial structures, power systems, transportation, and the oil and gas industry, and offer an efficient, flexible cabling system. Contact us for more information.

Related Searches of Perforated Cable Tray: Perforated Cable Tray Manufacturers|Perforated Cable Tray in India|Perforated Cable Tray Manufacturers in India|Perforated Cable Tray Suppliers|Perforated Cable Tray Suppliers in India|Perforated Cable Trays|Galvanized Wire Mesh Cable Tray Manufacturers. Our Perforated Cable Tray Manufacturers from India are leading Perforated Cable Tray Manufacturers and offering Perforated Cable Tray Suppliers in India, Perforated Cable Tray Exporters in India, Perforated Cable Tray Manufacturers offering Perforated Cable Tray in India, GI Perforated Cable Tray Manufacturer, Perforated Cable Trays, GI Perforated Cable Tray Suppliers, GI Perforated Cable Tray Exporters, Aluminium Perforated Cable Tray, Galvanised Iron Perforated Cable Tray, Stainless Steel Perforated Cable Tray In India, Perforated Cross, Top SS Cable Tray Manufacturer in India, Powder Coated Perforated Cable Trays, Stainless Steel Cable Trays in India.

Perforated Cable Tray Manufacturers in India

All Type of Perforated Cable Trays in India

Perforated Cable Tray Suppliers in India

Our Products

Cable Tray

We have carved a distinct niche in the market owing to the specialized skills, commitments and dedications or our workforce.

Read More

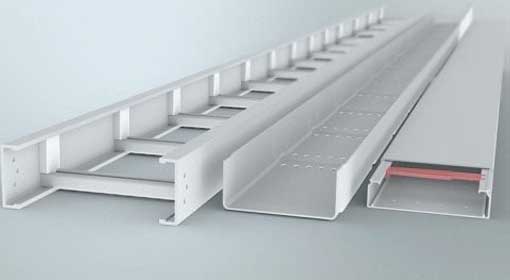

Perforated Type Cable Tray

We have carved a distinct niche in the market owing to the specialized skills, commitments and dedications or our workforce.

Read More

Ladder Type Cable Tray

We have carved a distinct niche in the market owing to the specialized skills, commitments and dedications or our workforce.

Read More

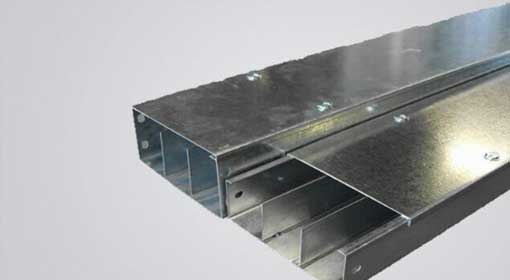

Box Type Cable Tray

We have carved a distinct niche in the market owing to the specialized skills, commitments and dedications or our workforce.

Read More

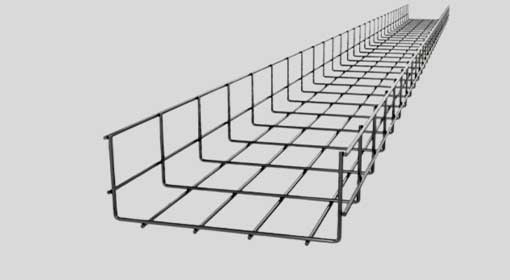

Wire Mesh Cable Tray

We have carved a distinct niche in the market owing to the specialized skills, commitments and dedications or our workforce.

Read More

FRP Cable Tray

We have carved a distinct niche in the market owing to the specialized skills, commitments and dedications or our workforce.

Read MoreFAQs for Perforated Cable Tray:

Usually constructed of steel (pre-galvanized, hot-dip galvanized), stainless steel, or aluminum, depending upon application condition and corrosion protection requirement

Take into account how many cables must be supported, cable size and weight, support span, and future addition space allowance when deciding size of tray and load rating proper.

Perforated cable tray fittings are used to supply varieties of clamps, support brackets, bends, tees, risers, covers, and dividers in a manner which makes it easy to set up and configure the cable route system.