- Home

- Earthing Electrode in India

Leading Earthing Electrode Manufacturers in India 2026|Earthing Electrode in India|Earthing Electrode Manufacturers

Earthing electrode manufacturers in India, suppliers and exporters of earthing electrode in India.Get earthing electrode manufacturers by Pratik Cabletray Pvt. Ltd. Contact Us now.

Searches Related to Earthing Electrode:Earthing Electrode Manufacturers in India, Earthing Electrode Suppliers in India, Earthing Electrode Exporters in India, Copper-Bonded Earthing Electrode, Earthing Electrode in India, Earthing Rod Manufacturers in India, Earthing Rod Suppliers in India, Earthing Rod Exporters in India, Copper-Bonded Earthing Electrode, Earthing Electrode, Earthing Electrode in India, GI Earthing Electrode, Earthing Electrode Solutions, Grounding Electrode Suppliers, Gel Earthing, Solid Copper Earthing, Copper Bonded Earthing, Chemical Earthing, Mat Earthing, Copper Rod, GI (Galvanized Iron) Pipe, Plate Electrode, Chemical Rod Electrode.

Pratik Cabletray Pvt. Ltd. is the leading earthing electrode manufacturers in India, as well as prominent earthing electrode suppliers and exporters in India. In this era of electricity, reliability and safety both depend on the unseen watchful eye: the earthing electrode.

With decades of tradition behind us, we have the experience and know-how to assist you. We have grown and developed to provide you with wisely solutions. Believe in our tradition. At the heart of every stable power system lies a dependable grounding solution. Our GI earthing electrodes suppliers in India, offer maximum conductivity, corrosion resistance, and long-term stability, ensuring protection for both human life and valuable electrical equipment.

Earthing Electrode Manufacturers in India - Advanced Grounding Solutions

It is the silent sentry that chivvies marauding currents back into the earth intact without harm, saving lives, equipment, and even entire operations. But considering all the many types and applications, locating the perfect earthing electrode is groping an impervious subterranean maze. Having these fundamentals in your industries will enable you to make good decisions and have a solid and effective grounding system. Let us start and earth your knowledge.

Why to Choose Earthing Electrode?

Successful earthing electrodes installation is not merely a question of compliance; it is an issue of safety necessity. These provide a useful low-resistance path, which redirects life-threatening fault currents from equipment and human beings. This safeguarding factor reduces the likelihood of electrical shock, avoids expensive damage, and contributes to useful and reliable operation in your industrial plant. Finally, earthing electrodes provide peace of mind and conditions of enhanced safety.

Types of Earthing Electrode Manufacturers in India:

Being as earthing electrode manufacturers in India, different types are there as per depend on effectiveness which are given below.

- Copper Rod: Copper or copper-bonded steel rod driven directly into the ground. With high conductance and corrosive resistance, it is a good, highly popular choice. Simple to install, especially in loose earth.

- GI (Galvanized Iron) Pipe: A pipe of tube-like shape made of galvanized iron drilled into the ground. It has a greater surface area than a rod, which will most likely give a better contact with the ground. It is an inexpensive grounding method in most situations.

- Plate Electrode: Copper or GI horizontal buried plate. It has a tremendous area of contact with the earth and thus finds application in the case of high resistivity soil. Burial depth is extremely important.

- Strip Electrode: A level metal strip (usually more copper or GI) in a trench. It is highly convenient in situations where rocks or shallow soil does not allow plates or rods to be driven in. Its effectiveness depends on the length of the strip.

- Chemical Rod Electrode: Rod that is filled with chemical compounds aimed at increasing the soil conductivity. These are effective in cases where soil is of poor quality and low resistance cannot be achieved using regular electrodes.

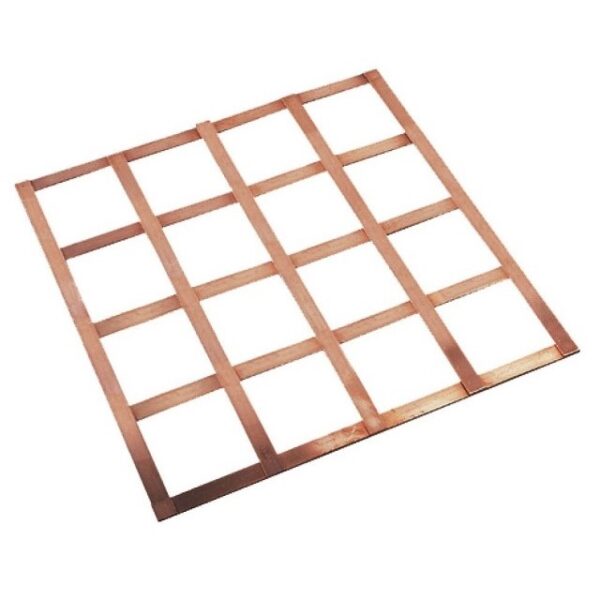

- Mat Earthing: Horizontal and vertical electrodes are integrated to form a network, commonly used in large-scale installations.

Technical Specification of Earthing Electrode:

We have added below a technical sheet of earthing electrode in India that provides more technical information such as:

| Feature | GI (Galvanized Iron) Pipe Electrode | Copper Bonded Steel Rod Electrode | Solid Copper Rod Electrode | GI (Galvanized Iron) Strip Electrode | Copper Strip Electrode | Chemical Earthing Electrode (Pipe in Pipe) |

|---|---|---|---|---|---|---|

| Material | Mild Steel with Hot-Dip Galvanization (as per IS 4759 or equivalent) | High Tensile Low Carbon Steel Core with Molecularly Bonded Copper Layer (99.9% purity, min. 250 microns) | Solid Electrolytic Grade Copper (min. 99.9% purity) | Mild Steel with Hot-Dip Galvanization (as per IS 4759 or equivalent) | Electrolytic Grade Copper (min. 99.9% purity) | GI/Copper Pipe (Outer) and GI/Copper Strip/Pipe (Inner), surrounded by Chemical Compound |

| Diameter/Size | Typically 38mm to 100mm (outer diameter) | Typically 12.7mm to 25mm (diameter) | Typically 12mm to 25mm (diameter) | Typically 25mm x 4mm to 50mm x 6mm (cross-section) | Typically 25mm x 3mm to 50mm x 6mm (cross-section) | Outer Pipe: 50mm to 150mm diameter; Inner Component: Various sizes |

| Length | Typically 2m to 4.5m (can be joined for greater depths) | Typically 1.2m to 3m (can be joined with couplings) | Typically 1.2m to 3m (limitations due to bending risk at greater lengths) | Variable, supplied in coils or cut lengths as per trench requirements | Variable, supplied in coils or cut lengths as per trench requirements | Typically 1m to 3m (overall length of the assembly) |

| Galvanization Thickness | Minimum 80-100 microns (for GI electrodes) | N/A (Copper bonding thickness is specified) | N/A | Minimum 80-100 microns (for GI strips) | N/A | N/A (Outer GI pipe is typically galvanized) |

| Copper Bonding | N/A | Minimum 250 microns (molecularly bonded) | N/A | N/A | N/A | N/A (Inner copper components may vary in thickness) |

| Jointing Method | Threaded couplings with GI or copper alloy material | Threaded couplings with copper alloy material | Threaded couplings with copper alloy material | Bolting with galvanized or tinned copper connectors | Bolting with brass or copper connectors | Typically welded or bolted connections for the pipe and internal components |

| Corrosion Resistance | Good (due to galvanization) | Excellent (combination of copper's resistance and steel's strength) | Excellent | Good (due to galvanization) | Excellent | Enhanced by chemical compound, good for electrode materials |

| Soil Suitability | Areas with moderate to high soil resistivity, high moisture content beneficial | Wide range, particularly effective in high resistivity soils | Suitable for corrosive soils and where very long service life is needed | Suitable for areas where deep driving is difficult, used in trenches | Suitable for areas where deep driving is difficult, used in trenches | Effective in poor conductive soils (rocky, sandy, dry) due to chemical enhancement |

| Installation | Vertical driving into the ground, can be watered for better conductivity | Vertical driving into the ground | Vertical driving into the ground (care needed to avoid bending) | Horizontal burial in trenches at specified depths (min. 0.5m) | Horizontal burial in trenches at specified depths (min. 0.5m) | Vertical burial, surrounded by specialized chemical compound |

Benefits of Earthing Electrode:

Serve as earthing electrode suppliers in India, for protection and stability different different benefits are there which are given below.

- Protection from Electric Shock: By providing a path of low resistance for fault currents, earth electrodes permit simple tripping of protective equipment like circuit breakers and thus prevent dangerous electric shock to man. This is required in every electrical installation.

- Equipment Protection: The earth electrodes divert lightning or fault currents from costly electronic equipment. This protects costly machinery and prevents costly downtime and industrial process loss.

- System Stability: Earthing strip a system offers an electrically stable voltage reference point to the system with low electrical noise and interference. This allows for more dependable operation of electrical and electronic equipment in the industrial process.

- Static Electricity Dissipation: Where there are flammable materials moving or sensitive electronics, earthing electrodes dissipate static electricity that tends to build up. This prevents fires, explosions, and component damage.

- Compliance with Regulation: All safety standards in the industry and electrical codes demand the implementation of efficient earthing systems. Proper installation of earthing electrodes will maintain compliance and avoid legal and insurance claims.

Applications of Earthing Electrode:

As earthing electrode exporters in India, applied as per infrastructure and industries need which are given below.

- Power Generation and Supply: Earthing electrodes exporters in India are employed heavily in power generation stations, substation stations, and transmission lines to protect equipment and human life from high fault currents and lightning strokes.

- Production Plants: From assembly plants to heavy equipment, earthing electrodes provide safety equipment and humans from electrical shock in diversified manufacturing processes with minimal production downtime.

- Telecommunications Infrastructure: Earthing is required to protect key communication equipment like servers, routers, and transmission towers from power surges and ensure flawless network operation without interruption.

- Oil and Gas Industry: Where hazardous areas like refineries and drilling sites are available, proper earthing prevents the production of static electricity and offers an innocuous fault current path to remove the risk of explosion.

- Data Centers: There ought to be a secure and stable electrical grounding system to safeguard precious and sensitive data. Earthing electrodes shield servers and networking equipment from power spikes and power fluctuations, ensuring data integrity and availability.

Pratik Cabletray Pvt. Ltd. is the recommended earthing electrode manufacturers in India and earthing electrode exporters in India. These electrodes are part of electrical systems utilized across all industries, particularly where equipment protection is a top priority, in addition to reliability in operation and protection. A suitable type should be chosen and properly installed to be the most important element of constructing an efficient grounding system that removes the risks of electricity, saves precious equipment, and attains security features. A good earthing system investment is the long-term guarantee of security and dependability for every industrial use. Discover top earthing electrode exporters in India offering copper bonded, GI, and chemical earthing solutions.

Earthing Electrode Manufacturers

Earthing Electrode Manufacturers in India

Earthing Electrode in India

Our Products

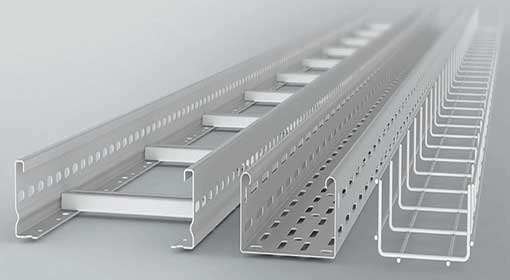

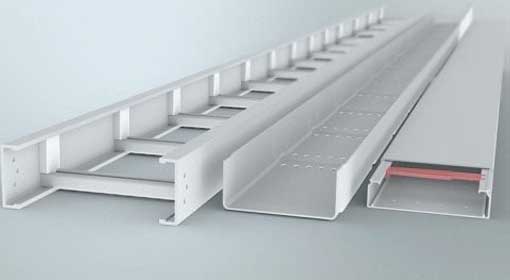

Cable Tray

We have carved a distinct niche in the market owing to the specialized skills, commitments and dedications or our workforce.

Read More

Perforated Type Cable Tray

We have carved a distinct niche in the market owing to the specialized skills, commitments and dedications or our workforce.

Read More

Ladder Type Cable Tray

We have carved a distinct niche in the market owing to the specialized skills, commitments and dedications or our workforce.

Read More

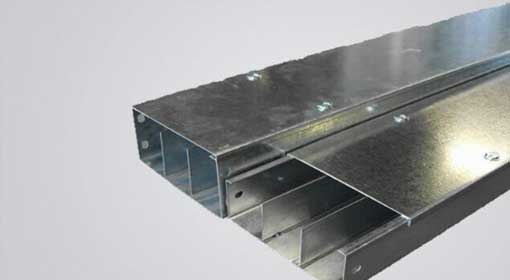

Box Type Cable Tray

We have carved a distinct niche in the market owing to the specialized skills, commitments and dedications or our workforce.

Read More

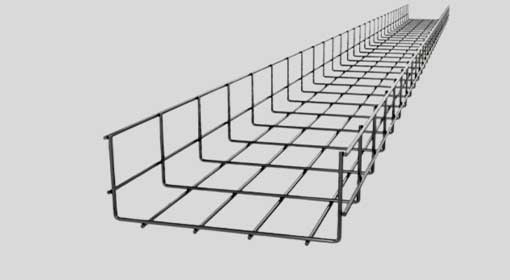

Wire Mesh Cable Tray

We have carved a distinct niche in the market owing to the specialized skills, commitments and dedications or our workforce.

Read More

FRP Cable Tray

We have carved a distinct niche in the market owing to the specialized skills, commitments and dedications or our workforce.

Read MoreFAQs of Earthing Electrodes

Soil resistivity, fault levels, available space, and cost. These all have some impact. It is strongly advised that you consult a good electrical engineer to get it right.

Depth depends on the conditions of soil and the size of the electrode. Rods and pipes commonly are installed so deep that these reach lower-resistivity earth, and plates and strips commonly have standardized depths of burial set forth in prevailing standards.

These should be inspected from time to time, typically once a year or as is required locally, to ensure the validity of the grounding system. Resistance values should be within acceptable limits.