- Home

- Instrumentation Tube Fittings in India

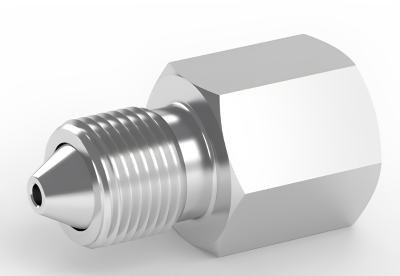

Instrumentation Tube Fitting Manufacturers in India|Instrumentation Tube Fitting Manufacturers|Instrumentation Tube Fittings in India

Pratik Cabletray Pvt. Ltd. is the leading instrumentation tube fitting manufacturers in India, suppliers, exporters of Instrumentation Tube Fitting in India. Instrumentation tube fittings are the trusted couplers providing free-flow and rock-solid integrity. Large product range has large cable tray accessories, and earth material.

We specialize in delivering precision-engineered tube fittings that are critical to ensuring leak-proof, high-performance connections in process control, instrumentation, and industrial piping systems. In demanding environments where precision and reliability are non-negotiable, instrumentation tube fittings act as the silent guardians—enabling seamless flow while maintaining rock-solid integrity. Our fittings are meticulously designed to withstand high pressure, temperature variations, and corrosive conditions, making them the ideal choice for mission-critical applications.

Instrumentation Tube Fitting Suppliers and Exporters in India

Imagine a world in which looseness and leakage are causing havoc with precise measurements and leading to processes of the utmost significance. These are the heroes of precision who remain unsung, the key to successful fluid and gas transfer, and the guarantee of secure and efficient working conditions. Join us on a tour of the world of these harmless-looking yet essential components.

Why to choose Instrumentation Tube Fitting?

As an Instrumentation tube fitting suppliers in India, selection is a promise of reliability and safety. Proper design consideration gives them utility and cost-effective and time-saving. Shape and material diversity gives versatility to the frame to accommodate various industrial processes. In short, these give assurance by providing the hard rock base of your critical fluid and gas process equipment.

Types of Instrumentation Tube Fitting:

As a leading instrumentation tube fitting manufacturers in India, different types are modified as per industries need which are given below.

- Cone and Thread (C&T) Fittings: C&T fittings are apt to be used where high as well as medium pressures are to be handled and establish a good seal. This is achieved by coning the tubing end and producing a corresponding countersink on the fitting body.

- Butt Weld Fitting: Usually chosen to be used in applications where there is a high resistance to vibration and fatigue, butt weld fittings create a permanent metal-to-metal union. The fitting is welded on the tubing ends and creates a solid leak-tight joint.

- Compression Fitting: As a top seller in all aspects, compression fittings are renowned for how simple these are to install and how this seal so well. These are made typically of a nut, a fitting body, and a ferrule or ferrules.

- Push-To-Connect Pneumatic Fitting: Designed to connect quickly and tool Lessley, these fittings make pneumatic system assembly easy. These are made up of an internal collet that clamps the tubing when pushed in and an external push button for simple release.

Technical Specification of Instrumentation Tube Fitting:

We have added below a technical sheet of instrumentation tube fitting in India and instrumentation tube fitting exporters in India that provides more technical information such as:

| Feature | Specification | Details |

|---|---|---|

| Type | Compression (Ferrule Type) | Most common: Double ferrule (front & back), Single ferrule available for specific low-pressure applications. |

| Cone & Thread | For high-pressure applications, requires tube end preparation (coning and threading). | |

| Weld (Socket Weld, Butt Weld) | Provides permanent connections, often used in high-temperature and high-pressure systems. Requires welding expertise. | |

| Push-to-Connect | For quick and easy connections in low-pressure pneumatic and hydraulic systems. May have limitations in vibration and temperature. | |

| Flare | Tube end is flared to create a seal against the fitting body. Common in automotive and refrigeration. | |

| Material | Stainless Steel (SS316/316L, SS304/304L) | Excellent corrosion resistance, high strength, wide temperature range. Most common for demanding applications. |

| Carbon Steel | Suitable for general industrial use with non-corrosive media. May require surface treatment for corrosion protection. | |

| Brass (CA360, CA377) | Good machinability and thermal conductivity, suitable for low to medium pressure applications with non-corrosive fluids. | |

| Alloy 400 (Monel) | Excellent resistance to corrosion in seawater, acids, and alkalis. Used in marine and chemical processing. | |

| Inconel 600/625 | High-temperature strength and corrosion resistance, used in aerospace and high-temperature chemical processes. | |

| Hastelloy C-276 | Exceptional resistance to a wide range of corrosive media, including strong oxidizing and reducing agents. | |

| Titanium (Grades 2 & 5) | High strength-to-weight ratio and excellent corrosion resistance, used in aerospace and chemical processing. | |

| Polymers (PTFE, Nylon) | Chemical resistance and low friction, suitable for specific low-pressure and corrosive applications. | |

| Size Range | Imperial | 1/16" to 2" Outer Diameter (OD) |

| Metric | 2 mm to 50 mm Outer Diameter (OD) | |

| Pressure Rating | Low Pressure | Up to 3000 psi (207 bar) |

| Medium Pressure | 3000 to 6000 psi (207 to 414 bar) | |

| High Pressure | 6000 to 15000 psi (414 to 1034 bar) and higher (for cone & thread) | |

| Temperature Range | Standard | -65°F to +800°F (-54°C to +427°C) - varies with material |

| High Temperature | Up to +1200°F (+649°C) or higher - varies with material | |

| Cryogenic | Down to -425°F (-254°C) - for specific stainless steel alloys | |

| Thread Types | NPT (National Pipe Taper) | Tapered thread, seals with thread interference. Common in North America. |

| BSPT (British Standard Pipe Taper) | Tapered thread, seals with thread interference. Common in Europe and Asia. | |

| BSPP (British Standard Pipe Parallel) | Parallel thread, requires a sealing washer or O-ring. Common in Europe and Asia. | |

| ISO Metric | Parallel threads with specific pitch and diameter. | |

| SAE/MS Straight Thread (UN/UNF) | Straight threads with O-ring boss or port connection. Common in hydraulic systems. | |

| Standards & Compliance | ASTM F1387 | Standard specification for performance of mechanically attached fittings. |

| ASME B31.3 | Process Piping Code - relevant for design and material selection. | |

| MSS SP-99 | Standard practice for instrumentation and control system piping. | |

| NACE MR0175/ISO 15156 | Material requirements for sour gas environments (specific alloys). | |

| PED (Pressure Equipment Directive) | European standard for pressure equipment. |

Benefits of Instrumentation Tube Fitting:

As an instrumentation tube fitting suppliers in India and instrumentation tube fitting exporters in India, as per maintenance purposes different benefits are there which are given below.

- Leak-Tight Fittings: Properly specified to high standards, these provide safe, leak-free sealing, eliminating costly loss of valuable media and system integrity. This reduces downtime, operating cost, and safety by removal of hazardous leaks.

- Temperature and High-Pressure Resistance: Instrumentation tube fittings suppliers in India are constructed sturdy and are suitable for use in severe operating conditions. This assures uniform performance in high-pressure and high-temperature operating conditions typical in the industrial setting.

- Simplicity in Installation and Maintenance: In the case of other joining processes, e.g., welding, tube fittings usually possess relatively simple installation steps that may be performed with just common hand tools. The installation will be quicker and easier, and re-orientation or maintenance easier.

- Flexibility of Use: The variation in material, size, and shape is very high, and instrumentation tube fittings can thus be used in very broad range of applications and industries. The flexibility ensures the potential of the final system design and component selection to meet some specifications.

- Better System Safety and Reliability: Through providing secure and reliable connections, these make industrial systems reliable and safe. These reduce the opportunities for failures, protect human beings, and enable processes to be in a place to operate flawlessly.

Applications of Instrumentation Tube Fitting:

As an instrumentation tube fitting exporters in India, it is applied in various sectors as per need and demand which are given below.

- Oil and Gas Industry: From Performance of processes, platform to refinery, these are useful in furnishing the medium for instrument connection of high-pressure procedure for operation, and hazardous chemicals.

- Chemical Process Plants: For holding corrosive and reactive chemicals under such conditions, proprietary tube fittings provide leak-tight connections in analysis equipment, sample lines, and process control systems. Material compatibility is the largest concern for long life and safety.

- Power Generation: Instrumentation tube fittings join pressure gauges, control modules, and sensors in conventional as well as green power plants to measure the important parameters like pressure, flow, and temperature. There has to be reliability for safe and smooth operation.

- Semiconductor Manufacturing: Ultra-purity is critical to semiconductor production and specialty stainless tube fittings provide contamination-free fluid and gas transfer of critical processing. Leak integrity is of lesser concern compared to product integrity.

- Pharmaceutical and Biotech:Instrumentation tube fittings exporters in India play an important role in installation of analytical instruments, bioreactors, and clean utility systems in highly regulated use here. Sanitary configurations and traceability are generally required.

Pratik Cabletray Pvt. Ltd. is the leading instrumentation tube fitting manufacturers in India, suppliers and exporters in India. Instrument fittings for double ferrule fittings are more than couplers; these are significant products that add efficiency, safety, and reliability to processes that function in billions of industries. Our versatility, inherent benefits, and extensive applications make our lone place in industry today. These contribute positively towards excellence of operation and process integrity in leak-tight, safe assembly.

Our Products

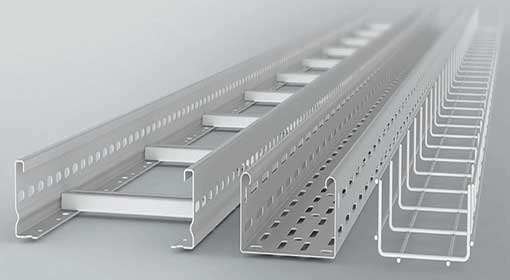

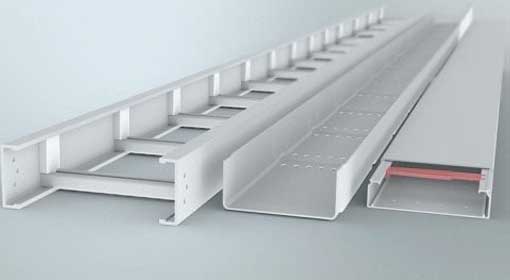

Cable Tray

We have carved a distinct niche in the market owing to the specialized skills, commitments and dedications or our workforce.

Read More

Perforated Type Cable Tray

We have carved a distinct niche in the market owing to the specialized skills, commitments and dedications or our workforce.

Read More

Ladder Type Cable Tray

We have carved a distinct niche in the market owing to the specialized skills, commitments and dedications or our workforce.

Read More

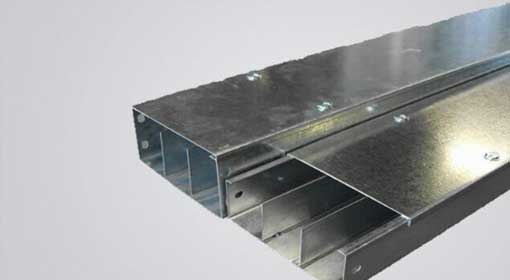

Box Type Cable Tray

We have carved a distinct niche in the market owing to the specialized skills, commitments and dedications or our workforce.

Read More

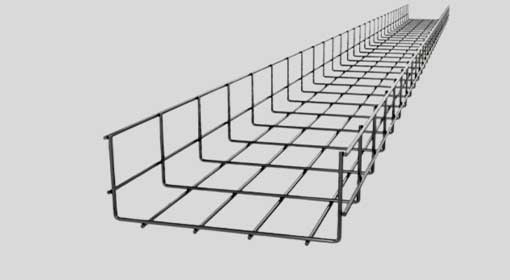

Wire Mesh Cable Tray

We have carved a distinct niche in the market owing to the specialized skills, commitments and dedications or our workforce.

Read More

FRP Cable Tray

We have carved a distinct niche in the market owing to the specialized skills, commitments and dedications or our workforce.

Read MoreFAQs on Instrumentation Tube Fittings:

Most commonly used materials are stainless steel (304, 316) and carbon steel, brass, and specialty alloys like Monel and Hastelloy for corrosive use. Depending on the pressure, media, and temperature requirements, selection is made

Right size should be equal to the outer diameter of tubing material. Tubing OD should be taken very accurately so that a proper and leakage-free joint can be created.

NPT (National Pipe Thread) and taper thread designation used in North America, while BSP is British Standard Pipe tapered (BSPT) or parallel (BSPP) used elsewhere in the rest of the world other than North America. These two cannot be replaced.