- Home

- GI Grating in India

GI Grating manufacturers in India|Leading GI Grating manufacturers|GI Grating in India|Galvanized Grating Manufacturers|Top Best GI Grating manufacturers

Leading GI Grating Manufacturers in India or Galvanized Grating Manufacturers, Suppliers, Exporters of GI Grating in India | Pratik Cabletray Pvt. Ltd. As we are leading GI grating manufacturers in India we are manufacturing Galvanized Grating Manufacturers, Welded Steel Grating, Swage Locked Grating, Pressure Locked Grating, Heavy Duty Grating, Molded Grating in India. Get a Quote Now for GI Grating Manufacturers in India.

Searches Related to GI Gratings: Galvanized Grating Manufacturers, GI Grating manufacturers in India, GI Grating Exporters in India, GI Grating Suppliers in India, Hot Dip GI Grating manufacturers, Hot Dip GI Grating Suppliers, Hot Dip GI Grating Exporters, GI Grating in India, Galvanized Iron Grating in India, GI Grating Suppliers, GI Grating Manufacturers, GI Grating Exporters, GI Grating, hot dip galvanize grating, galvanized iron gratings, hot dip galvanized gratings, gi floor gratings, heavy duty gi gratings and medium duty gi floor gratings, Welded Steel Grating, Swage Locked Grating, Pressure Locked Grating, Heavy Duty Grating, Molded Grating, MS GI Grating, Steel GI Grating, Mild Steel GI Grating, Fabricated Steel Grating, Galvanised Steel Grating Industrial GI Grating

Pratik Cabletray Pvt. Ltd. is the leading GI grating manufacturers in India, as well as prominent GI grating suppliers and exporters in India. Emphasis on innovation thinking leading the way, we are making cable management technology history. We keep innovating solutions for emerging needs of the electrical industry. Bank with us for out-of-the-box ideas. With a firm belief in innovation-driven growth, we are not only delivering products—we're shaping the future of cable management and structural support systems.

With every grating we manufacture, we aim to set a new benchmark in strength, safety, and efficiency. Our galvanized iron (GI) gratings are engineered using state-of-the-art technology and high-quality materials to ensure robust performance and long-term durability across a wide range of industrial applications.

GI Grating Manufacturers in India

GI Grating is a marvel of engineering and boasts a strong mix of strength, pliability, and economy. From cacophonous factories to state-of-the-art offshore facilities, this high-end performance product is offering secure pedestrian and efficient drainage, the backbone of the majority of industries. Let's venture into the world of GI and it emerges as the optimum option for extreme use.

Types of GI Grating Manufacturers in India:

Being as GI grating manufacturers in India, and GI Grating Suppliers in India, these types are modified accordingly different requirement and as per industrial application which are given below.

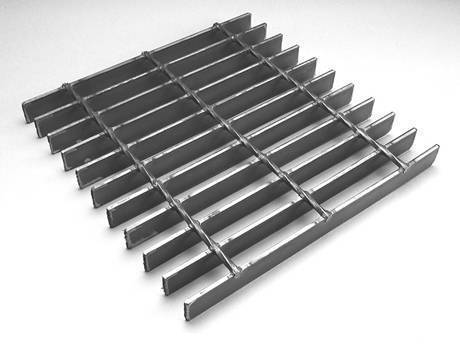

- Welded Steel Grating: Joins bearing bars and crossbars to make this shape. It is stiff and rigid and has to be used where loads are heavy, i.e., factory floors and highways. Fused joints assist in supporting structure load as well as passing weight uniformly.

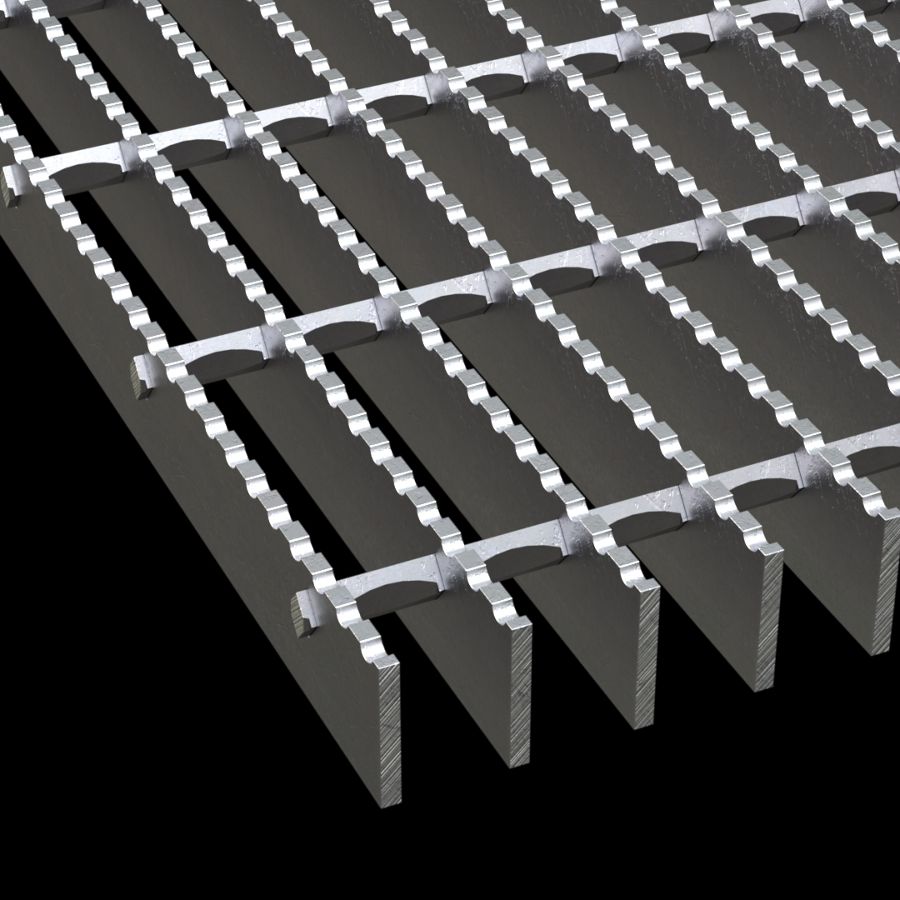

- Swage Locked Grating: Mechanical crossbars in this become locked into notched bearing bars. This provides a clean, level surface and is employed most commonly in architectural application and pedestrian walkways. Close locking provides stability and bars cannot be moved.

- Pressure Locked Grating: Like the swage locked but being held in place by pressure of hydraulic force against bearing bars. This provides a rigid and stiff grating adequate for medium loading requirement. Pressure locking provides an immovable and dimensionally stiff panel.

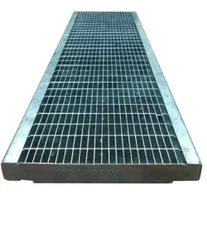

- Heavy Duty Grating: Constructed with thicker bearing bars and narrower on-center spacing, this line will carry extremely heavy loads and is used for airport runway and other heavily extreme use industrial application.

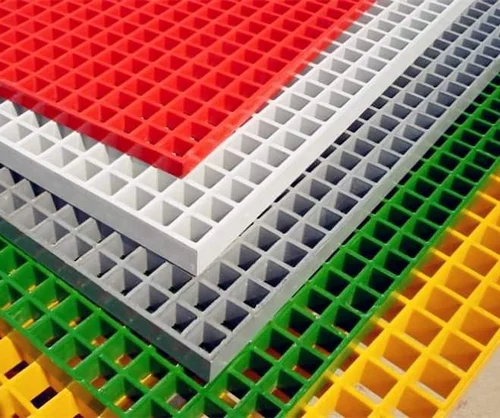

- Molded Grating: While typically produced with fiberglass reinforced plastic (FRP), GI can also be molded to take advantage where complex patterns or curved shapes are required. This offers design flexibility with maintenance of galvanized steel corrosion protection.

Technical Specification of GI Grating Manufacturers:

We have added below a technical sheet of GI grating in India and GI grating suppliers in India that provides more technical information such as:

| Specification Category | Parameter | Typical Values/Ranges | Units | Notes |

|---|---|---|---|---|

| Material | Steel Grade | Mild Steel (Q235, ASTM A36, IS 2062), other grades available | - | The base material significantly impacts strength and weldability. |

| Coating | Hot-Dip Galvanized (HDG) | μm (microns) | Coating thickness varies based on standards (e.g., ASTM A123, BS EN ISO 1461, YB/T 13912). Typically 40-80 μm or more. | |

| Bearing Bars | Size (Width x Thickness) | 20x3 to 100x10 (or more) | mm | Determines the primary load-bearing capacity. |

| Pitch (Center to Center Spacing) | 12.5 to 100 (common: 30, 30.16, 30.3, 34.3, 40, 60) | mm | Influences load distribution and opening size. | |

| Surface Type | Plain, Serrated | - | Serrations provide enhanced slip resistance. | |

| Cross Bars | Size (Diameter or Width x Thickness) | Round (4 to 10), Flat (e.g., 6x6, 8x8, 10x5) | mm | Connect and stabilize the bearing bars. |

| Pitch (Center to Center Spacing) | 30 to 200 (common: 50, 76, 100, 101.6) | mm | Affects the stability and opening size. | |

| Grating Panel | Width | Up to 1000 (or more, depending on handling) | mm | Standard and custom widths available. |

| Length | Up to 6000 (or more, depending on transportation) | mm | Standard and custom lengths available. | |

| Thickness | Varies based on bearing bar size | mm | Overall thickness is determined by the bearing bar thickness. | |

| Mesh/Opening Size | Clear Opening Between Bearing Bars | Varies based on bearing bar size and pitch | mm | Determines what size of objects can pass through. |

| Clear Opening Between Cross Bars | Varies based on cross bar size and pitch | mm | ||

| Load Capacity | Uniform Load (Distributed Load) | Varies significantly based on design and span | kN/m², kg/m² | Specified as the maximum load the grating can withstand over its entire surface area. |

| Point Load (Concentrated Load) | Varies significantly based on design and span | kN, kg | Specified as the maximum load applied on a small area (e.g., 200x200 mm). | |

| Deflection | Typically limited to L/200 or a specific mm value | mm | Maximum allowable bending under load (L = span). | |

| Manufacturing Standards | Common Standards | YB/T 4001.1-2007 (China), BS 4592 (UK), ASTM A36 (USA), AS 1657 (Australia), ANSI/NAAMM (MBG 531) | - | Ensures quality and interchangeability. |

| Surface Finish Options | Additional Finishes | Painted, Powder Coated | - | For specific aesthetic or enhanced corrosion resistance requirements. |

Benefits of GI Grating

Serve as GI grating suppliers in India, benefits like safety, protection and cost effectiveness and many more are there which are given below.

- Unparalleled Strength and Plasticity: The strength given in the steel by the zinc plating naturally along with the wisdom for protection leads to a robust material that can resist goliath loads and endure extreme conditions with its working life increased.

- Better Corrosion Protection: Galvanizing forms a sacrificial zinc coating that shields the underlying steel against corrosion and rusting and renders it suitable for use outside, as well as for safe usage in chemically aggressive environments.

- Increased Safety: No open grid structure offers better grip and less room for slipping and, apart from this, offers better liquid and debris drainage in an attempt to further stabilize the workplace condition. Snow and ice cannot be caused to build up with open grid structure during low temperatures.

- Ease of Installation and Maintenance: GI Grating is easy to install due to its light weight and convenience, and is therefore easy to install. Openness also promotes ease of inspection and cleaning with low maintenance requirements and downtime.

- Cost-Effectiveness: Although comparatively costly to install, the low cost of maintenance, long life, and low replacement needs make GI Grating extremely cost-effective in the long run. The strength keeps lifecycle costs intact.

Applications of GI Grating

As GI grating exporters in India and GI grating manufacturers in India, it is applied in different places as per nature and different points considered which are given below.

- Industrial Flooring and Platforms: Providing safe, level walkways, working surfaces, and mezzanines for manufacturing plants, warehouses, and processing plants. Open structure welcomes penetration of light and ventilation and provides safe footing for equipment and personnel.

- Walkways and Pedestrian Bridges: Providing slip-reducing, abrasion-resistant pedestrian walkways for use over overpass, public spaces, and parks. Heavy-duty design provides safety and durability in heavy traffic use, mesh size to provide specific requirements.

- Drainage Grates and Covers: Effective draining of water and liquids from roadways, factories, and parking lots. Hot Dip Galvanised Steel Bar Grating Open grid pattern will have maximum rate of flow but will allow traffic from vehicles.

- Stair Treads: Providing safe, non-slip stairs to industries and for commercial purposes, which makes them harder and safer for heavy use areas. Serrations on conventionally serrated surfaces give friction and lead to zero accidents.

- Security Fencing and Barriers: Put in place an impenetrable and robust bar of security in industries, powerhouses, and other hazard zones. Glass structure provides visibility, strongly deterrent in nature.

Pratik Cabletray Pvt. Ltd. is the recommended GI grating manufacturers in India, it is load-carrying material in a variety of industries with the ideal combination of strength, toughness, safety, and economy. Resistant to harsh conditions and heavy loads but easy installation with little maintenance make it a wise and cost-effective option in many applications. From protecting people on upper floors to effective drainage on highways, GI Grating returns investment time and again as a valuable investment in long-life infrastructure.

Related Searches of GI Grating: GI Grating manufacturers in India, GI Grating Exporters in India, GI Grating Suppliers in India, Hot Dip GI Grating manufacturers, Hot Dip GI Grating Suppliers, Hot Dip GI Grating Exporters, GI Grating in India, Galvanized Iron Grating in India, GI Grating Suppliers, GI Grating Manufacturers, GI Grating Exporters, GI Grating, hot dip galvanize grating, galvanized iron gratings, hot dip galvanized gratings, gi floor gratings, heavy duty gi gratings and medium duty gi floor gratings, Welded Steel Grating, Swage Locked Grating, Pressure Locked Grating, Heavy Duty Grating, Molded Grating, MS GI Grating, Steel GI Grating, Mild Steel GI Grating, Fabricated Steel Grating, Galvanised Steel Grating Industrial GI Grating

GI Grating Manufacturers in India

GI Gratings in India

GI Grating Suppliers in India

Our Products

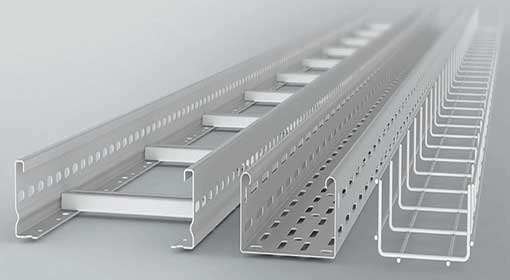

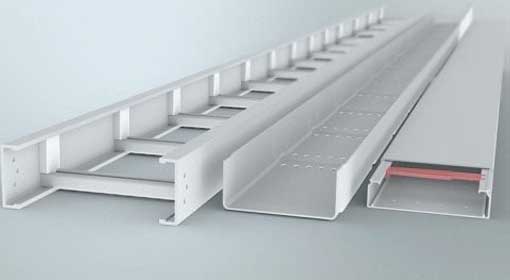

Cable Tray

We have carved a distinct niche in the market owing to the specialized skills, commitments and dedications or our workforce.

Read More

Perforated Type Cable Tray

We have carved a distinct niche in the market owing to the specialized skills, commitments and dedications or our workforce.

Read More

Ladder Type Cable Tray

We have carved a distinct niche in the market owing to the specialized skills, commitments and dedications or our workforce.

Read More

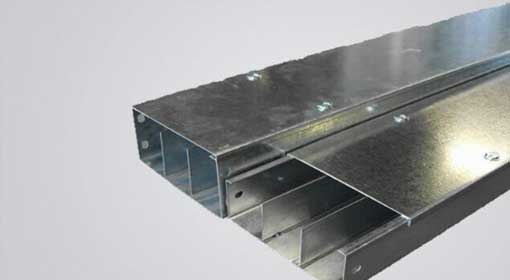

Box Type Cable Tray

We have carved a distinct niche in the market owing to the specialized skills, commitments and dedications or our workforce.

Read More

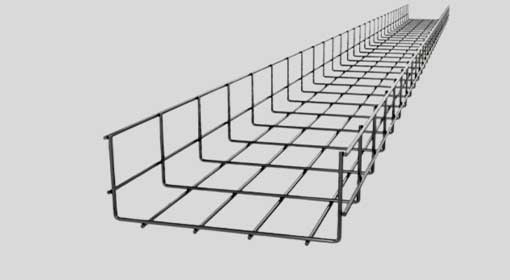

Wire Mesh Cable Tray

We have carved a distinct niche in the market owing to the specialized skills, commitments and dedications or our workforce.

Read More

FRP Cable Tray

We have carved a distinct niche in the market owing to the specialized skills, commitments and dedications or our workforce.

Read MoreGI Grating FAQs:

Standard panel sizes differ by manufacturer, but standard widths are 3 feet and 4 feet, and standard lengths are 10 feet to 24 feet. Special sizes are also manufactured to specifications.

Welded grating is not the same as swage locked grating. Welded grating consists of bearing bars and crossbars that are welded and provides maximum strength. Swage locked grating mechanically fastens the bars together to create a level surface which is usually walked upon by human beings.

Take into consideration load requirement, traffic rate, environment exposure (moisture or chemical), and appearance. Wise to speak with a manufacturer of gratings about what and how.