- Home

- FRP Cable Tray in India

FRP Cable Tray Manufacturers in India-2026|FRP Cable Tray Manufacturers|FRP Cable Trays in India

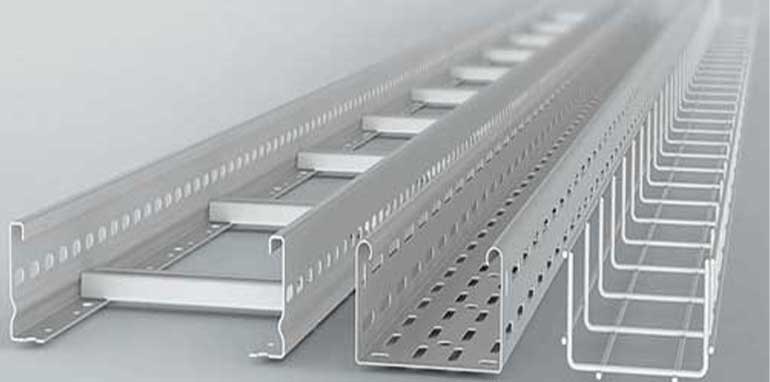

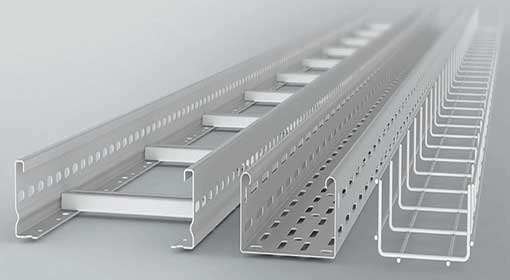

We are leading FRP Cable Tray Manufacturers in India, suppliers, exporters of FRP Cable Tray in India by Pratik Cabletray Pvt. Ltd. As we are leading FRP Cable Tray Manufacturers we are offering Ladder Type FRP Cable Tray, Solid Bottom Type FRP Cable Tray, Trough Type FRP Cable Tray, Channel Type FRP Cable Tray, Wire Mesh Type FRP Cable Tray in India. Get Best Quote Now.

Pratik Cabletray Pvt. Ltd. is the leading FRP cable tray manufacturers in India, as well as prominent FRP cable tray suppliers and exporters in India. We provide customized solutions and industry-leading service to bring success to your project. Your requirements occupy the prime place in what we do. The future generation solution developed for uncompromising strength, durability, and performance. Our commitment to innovation, quality, and customer satisfaction has made us a preferred choice for industries across the nation and beyond.

Searches Related to FRP Cable Tray Manufacturers:FRP Cable Tray Manufacturers in India, FRP Cable Tray Suppliers in India, FRP Cable Tray Exporters in India, Fibreglass Reinforced Plastic Suppliers In India, FRP Cable Tray in India, Fibreglass Reinforced Plastic Exporters In India, Fibreglass Reinforced Plastic Manufacturers In India, FRP Cable Tray, frp cable tray price, Frp Cable Tray Manufacturers, FRP Cable Tray Cross Manufacturers, FRP Cable Tray Cross Suppliers, FRP Cable Tray Cross Exporters, Ladder Type FRP Cable, Solid Bottom Type cable, Channel Type, Top FRP Cable Tray Manufacturers in India

We specialize in customized FRP cable tray suppliers in India that cater to a wide range of applications and industries, including power plants, chemical factories, refineries, and infrastructure projects. Our FRP (Fiber Reinforced Plastic) cable trays are designed for unmatched strength, corrosion resistance, and long-term durability, ensuring optimal performance in even the most demanding environments.

FRP Cable Tray Manufacturers in India

See how these ultra-light yet ultra-durable systems are transforming industries, giving a corrosion-free, electrically non-conductive, and low-maintenance path to your mission-critical cables. And now let us move on to the universal shapes, strong benefits, and generic applications that make FRP cable trays suppliers in India, the intelligent solution for future-proof infrastructure.

Why Choose our FRP Cable Tray Manufacturers?

FRP cable trays exporters in India that offers: Unparalleled life with enhanced corrosion and weather resistance. Improved safety through its non-conductivity, eliminating the risk of grounding. Reduced cost of installation through our lightweight but durable structure. No maintenance, which means a mammoth long-term cost saving.

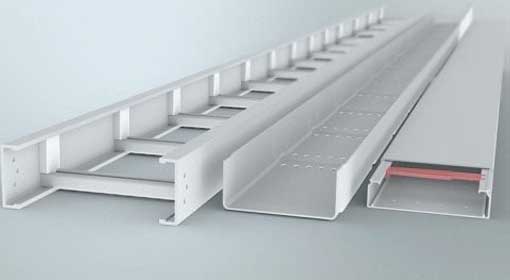

Types of FRP Cable Tray:

Being as FRP cable tray manufacturers in India, as per shape, size and performance types are used in industrial applications which are given below.

- Ladder Type: Total exposure and open rungs for maximum air flow, best suited for high-performance application in heavy-duty power and control cable runs.

- Solid Bottom Type: Provides total protection of cables from the outer environment and mechanical stress, ideally suited for sensitive data and communications cables.

- Trough Type: Provides half-enclosure with slotted or punched bottom for half-ventilation and covering of cables, widely used in standard industrial applications.

- Channel Type: An economical solution to instrumentation wiring and short cable lengths with sufficient support and organization in small spaces.

- Wire Mesh Type: A very lightweight and light-duty cable tray type with simple routing of cabling and ventilation, primarily utilized in telecom as well as data center installations.

Technical Specification of FRP Cable Tray:

We have added below a technical sheet of FRP cable tray in India and FRP cable tray manufacturers in India that provides more technical information such as:

| Specification Category | Parameter | Value/Range |

|---|---|---|

| Material of Construction | Resin Type | Polyester (Isophthalic, Orthophthalic), Vinyl Ester (Standard, Fire Retardant), Epoxy |

| Reinforcement Material | E-Glass Fiber (Rovings, Mats), Other Glass Types (ECR Boron-Free) | |

| Glass Content | 55% - 70% (by weight) | |

| Manufacturing Process | Pultrusion | |

| Mechanical Properties | Tensile Strength | 200 - 600 MPa |

| Flexural Strength | 300 - 800 MPa | |

| Compressive Strength | 150 - 400 MPa | |

| Impact Strength (Izod Notched) | 50 - 200 J/m | |

| Tensile Modulus | 15 - 35 GPa | |

| Flexural Modulus | 10 - 30 GPa | |

| Load Bearing Capacity (UDL) | 10 - 150+ kg/m | |

| Maximum Deflection | L/100 to L/200 (where L is the support span) | |

| Physical Properties | Density | 1.6 - 2.0 g/cm³ |

| Water Absorption | <0.5 % | |

| Coefficient of Thermal Expansion | Similar to or lower than aluminum | |

| UV Resistance | Excellent (UV Stabilized Resins, Additives as per ASTM G154) | |

| Corrosion Resistance | Excellent resistance to acids, alkalis, solvents, salts, and harsh chemical environments | |

| Electrical Properties | Dielectric Strength | 10 - 20 kV/mm |

| Surface Resistivity | 10¹² - 10¹⁴ Ω | |

| Volume Resistivity | 10¹⁴ - 10¹⁶ Ω·cm | |

| Fire Performance | Flame Spread Rating | Class A/1 (ASTM E84), Low Flame Spread (BS 476 Part 7 Class 1), Fire Retardant as per IS 6746 |

| Smoke Density | Low Smoke Generation (ASTM E84) | |

| Limiting Oxygen Index (LOI) | 28 - 35+ % | |

| Dimensions | Width | 50 - 1200 mm |

| Height (Side Rail Height) | 50 - 150 mm | |

| Length | 3000 - 6000 (Standard), Custom lengths available mm | |

| Thickness | 3 - 6 mm | |

| Rung Spacing (Ladder Type) | 150 - 300 mm | |

| Rung Dimensions (Ladder Type) | 25x25, 30x30, etc. mm | |

| Accessories | Coupler Plates | FRP/GRP with Stainless Steel (SS304/SS316) Bolts & Nuts |

| Bends (Horizontal & Vertical) | 45°, 90°, Custom Angles, Various Radii | |

| Tees, Crosses, Reducers | FRP/GRP Construction, Various Configurations & Sizes | |

| Covers | FRP/GRP, Solid or Ventilated | |

| Support Systems | FRP/GRP Struts, Clamps, Hangers, Base Plates, etc. | |

| Standards & Compliance | Material Standards | ASTM D3917, BS 3532, ISO 9001 |

| Cable Tray Standards | NEMA FG-1, IEC 61537, UL 568, CSA C22.2 No. 126.1, EN 61537 | |

| Fire Safety Standards | ASTM E84, BS 476, UL 94, IEC 60695, IS 6746 | |

| Installation | Joining Method | Bolted connections using stainless steel fasteners |

| Handling | Lightweight, easy to cut, drill, and assemble on-site |

Benefits of FRP Cable Tray:

Serve as FRP cable tray suppliers in India, different benefits are provided for maintenance, safety purposes which are given below.

- Enhanced Corrosion Resistance: Over metal trays, FRP contains inherent resistance towards severe weathering, chemicals, and corrosion, thereby doubling the system's life as well as lowering the cost of maintenance.

- Lightweight but High Strength: FRP possesses a strength-to-weight ratio which cannot be outperformed as it is lighter in weight than steel or aluminum, simple to fit, decreasing the structural load, and negating the transportation cost.

- Non-Conductive and Safe: FRP is an improved electrical insulator, ruling out the grounding danger and generating safe cable installations for individuals around the surrounding world.

- Low Maintenance: FRP's corrosion resistance and inherent strength reduce the frequency of periodic inspection, painting, or replacement, which pays off in the long run as a cost-saving measure and as a time loss avoidance measure.

- Flexibility in Design: FRP Cable Trays manufacturers in India are pliable and can be molded into a wide range of shapes and sizes, and because of this, it is not difficult for it to be molded into special project specifications and readily address demanding layouts.

Applications of FRP Cable Tray:

As FRP cable tray exporters in India, applied for enhancing resistance and maintaining performance which are given below.

- Chemical and Petrochemical Plants: FRP's resistance to corrosion is well-suited to cable management where exposure to harsh chemicals, acids, and solvents is likely and will provide long-term performance.

- Wastewater Treatment Plants: FRP cable trays withstand wastewater treatment plant's corrosive, wet condition and are a low-maintenance, long-life cable management solution.

- Marine and Offshore Environment: Corrosion-resistant characteristics of FRP towards sea water and severe environment conditions make it a strongly feasible material for ship cable cabling, oil rig cabling, and seacoast base installation cable cabling and making it safe with long endurance.

- Structure Infrastructure (Bridges, Tunnels): FRP's strong weight ratio and weight savings provide light structure weights with enhanced weather resistance and hence is most suitable to severe infrastructure specifications.

- Power Generation and Distribution: FRP cable trays' weather and electrical non-conductivity allow a safe and reliable power and control cable distribution and management system for power substations and power plants.

Pratik Cabletray Pvt. Ltd. is the recommended FRP cable tray manufacturers in India, trays are a revolutionary cable management breakthrough technology that offers an extremely highly desired package of durability, strength, safety, and affordability. With lightness, resistance to corrosion, and non-conductivity, FRP cable trays will be a top priority option in place of the conventional metal cable system as a diversified high-performance application in industry as well as infrastructure. With FRP cable trays exporters in India, companies can achieve longer reliability, eliminate catastrophic maintenance cost, and improve the degree of safety as far as our electric as well as communications grid is concerned too. Contact us for free quote.

FRP Cable Tray Manufacturers

FRP Cable Tray Manufacturers in India

FRP Cable Tray in India

Our Products

Cable Tray

We have carved a distinct niche in the market owing to the specialized skills, commitments and dedications or our workforce.

Read More

Perforated Type Cable Tray

We have carved a distinct niche in the market owing to the specialized skills, commitments and dedications or our workforce.

Read More

Ladder Type Cable Tray

We have carved a distinct niche in the market owing to the specialized skills, commitments and dedications or our workforce.

Read More

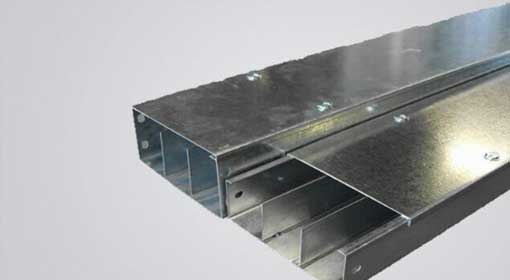

Box Type Cable Tray

We have carved a distinct niche in the market owing to the specialized skills, commitments and dedications or our workforce.

Read More

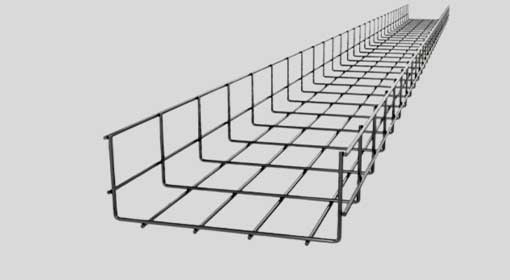

Wire Mesh Cable Tray

We have carved a distinct niche in the market owing to the specialized skills, commitments and dedications or our workforce.

Read More

FRP Cable Tray

We have carved a distinct niche in the market owing to the specialized skills, commitments and dedications or our workforce.

Read MoreFRP Cable Trays FAQs

More to buy though cost savings long term by lesser maintenance and higher life tends to make FRP economical.

Yes, FRP high strength-to-lightweight design can be designed for heavy cable load carrying based upon design and used resin system.

FRP can be specified with fire retardant additives to meet specific requirements for flammability. Be sure to confirm the fire rating of your chosen FRP system for your intended application.