- Home

- Flameproof Push Button Station in India

Flameproof Push Button Station Manufacturers in India|Flameproof Push Button Station in India

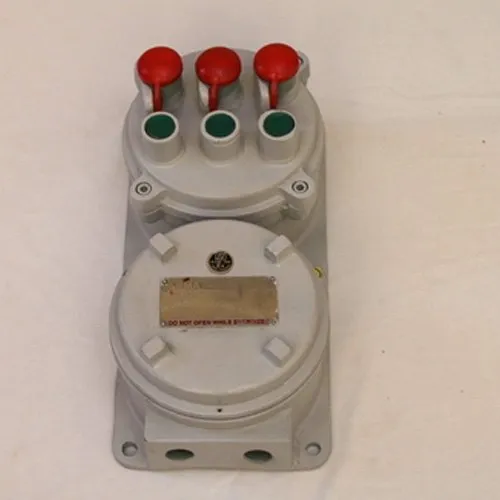

We are flameproof push button station manufacturers in India, suppliers, exporters of flameproof push button station in India. As we are leading manufacturers of flameproof push button station offering quality and reliable flameproof push button stations in India by Pratik Cabletray Pvt. Ltd.Pune, India. As we are best flameproof push button station manufacturers we are offering Single Push Button Station, Multi-Push Button Station, Emergency Stop Station, Pendant Push Button Stations, Specialized Control Stations in India.

We are offering Flameproof Push Button Station Manufacturers in India, Flameproof Push Button Station Suppliers in India, Flameproof Push Button Station, Flameproof Push Button Station in India, Flameproof Push Button Station India, Top Flameproof Push Button Station Manufacturers in India, Flameproof Push Button Station Exporters in India, Flameproof On Off Push Button, Flameproof Reversed Forward Push Button, Flameproof Weather-proof Push Button Station, Push Button Station, Single Push Button Stations Manufacturers in India, Multi-Push Button Stations Manufacturers in India, Pendant Push Button Stations, Specialized Control Stations, Emergency Stop Stations, Flameproof Indirect Entry Push Button, Flameproof Control Station For Industrial, 10A Flameproof Local Control Station, Clean Room Push Button Station, Top Flameproof Push Button Station Manufacturer in India, Flameproof Push Button Station Manufacturers in India, Flameproof Indirect Entry Push Button Manufacturers in India, Flameproof Switch Socket Manufacturers in India, Flameproof Weatherproof Push Button Station Manufacturers in India, Clean Room Push Button Station in India, Flameproof Push Button Stations Manufacturer from India, Flameproof EOT Crane Pendant Push Button Station in India, Flameproof Industrial Push Button Station in India, Explosion Proof Push Button Station in India, Flameproof On Off Push Button in India, Flameproof On Off Push Button Station in India

Pratik Cabletray Pvt. Ltd. is the leading flameproof push button station manufacturers in India, as well as prominent flameproof push button station suppliers and exporters in India. By sustainable values and green manufacturing, we strive hard to minimize our carbon footprint and provide the finest quality of products.

Our flameproof push button stations are designed to perform reliably in hazardous environments, offering superior protection against sparks, dust, and flammable gases. Engineered with precision and manufactured under strict quality control standards, our products are certified for durability, efficiency, and safety compliance, ensuring complete peace of mind for our clients.

Flameproof Push Button Station Manufacturers in India

flameproof push button station Manufacturers in India are security guardians, developed with utmost caution in order to preserve explosion or sparks within and thereby avoid our ignition of the ambient air. These very critically needed devices make apparatus safe to operate and work satisfactorily in explosive environments, safeguarding man and equipment. Discover the immense realm of flameproof push button stations Exporters in India, our rudimentary benefits, and our myriad applications across a variety of industries.

Why to Choose Flameproof Push Button Station?

Choosing flameproof push button stations suppliers in India is a precautionary choice to ensure safety in potential explosive environments. These give confidence by greatly reducing the likelihood of disastrous accidents. Our rugged construction guarantees stable and long-term operation in harsh industrial environments. Spending on these focused control devices shows commitment to regulatory compliance and safe operation.

Types of Flameproof Push Button Station:

As a flameproof push button station manufacturers in India, different types are modified as push button needed in industry as follow.

- Single Push Button Station: These are small enclosures containing a single or double push button for elementary start/stop or control operations. These suit most local control of a solitary machine or process within potentially risky locations.

- Multi-Push Button Station: Indoor use for multiple push button, selector switch, or lighting operation, these give complete control for intricate processes. Multiple operations are controlled from one safe location.

- Emergency Stop Station: Large, easy-to-see mushroom-headed red buttons, these units make for immediate shut-down of equipment in emergency application. Heavy-duty construction ensures use when operation is most critical.

- Pendant Push Button Stations: Hung below ceiling support, these stations provide mobility and equipment control from a remote position. These are used generally for crane, hoist, and other material handling machine control.

- Specialized Control Station: Specifically designed to counter unique operating requirements, these stations may have an assortment of control components, enclosures, and wire configurations. These offer versatility in special and stringent applications within hostile environments.

Technical Specification of Flameproof Push Button Station:

We have added below a technical sheet of Flameproof Push Button Station in India that provides more technical information such as:

| Specification Category | Parameter | Typical Advanced Values/Features | Notes |

|---|---|---|---|

| Hazardous Area Certification | Zone Classification | Zone 1 & 2 (Gas Groups IIA, IIB, IIC), Zone 21 & 22 (Dust Groups IIIA, IIIB, IIIC) | Refer to specific certification (e.g., ATEX, IECEx, UL, CSA) for detailed gas and dust group compatibility. |

| Protection Concept | Ex d (Flameproof Enclosure), Ex tb (Protection by Enclosure for Dust) | Combination protection methods (e.g., Ex d + Ex tb) may also be available. | |

| Temperature Class | T4, T5, T6 (depending on the model and ambient temperature range) | Ensures the surface temperature of the enclosure remains below the ignition temperature of surrounding gases or dusts. | |

| Electrical Specifications | Rated Voltage (Ui) | Up to 690V AC/DC | Varies based on the contact block and application requirements. |

| Rated Current (Ie) | Up to 16A (AC-15, DC-13 duty), higher ratings available with specific contact blocks | Corresponds to the switching capacity of the contact blocks. | |

| Contact Configuration | 1NO, 1NC, 2NO, 2NC, 1NO+1NC, etc. (single or double pole options) | Multiple contact arrangements allow for versatile control and indication functions. | |

| Utilization Category | AC-15, DC-13 (inductive loads), AC-1, DC-1 (resistive loads) | Defines the type of electrical load the contacts are designed to switch reliably. | |

| Short-Circuit Protection | Suitable for use with appropriately rated fuses or circuit breakers | Ensures safety in case of electrical faults. | |

| Insulation Resistance | ≥ 100 MΩ at 500V DC | Indicates the quality of insulation and prevents leakage currents. | |

| Dielectric Strength | ≥ 2.5 kV AC for 1 minute between live parts and enclosure | Ensures the insulation can withstand high voltage without breakdown. | |

| Mechanical Specifications | Enclosure Material | Cast Aluminum Alloy (LM6, A356, etc.), Stainless Steel (SS304, SS316L) | Provides robust mechanical protection and corrosion resistance suitable for industrial environments. |

| Ingress Protection (IP) Rating | IP66, IP67 | Ensures protection against dust and water ingress, suitable for harsh outdoor and washdown environments. | |

| Impact Resistance (IK) Rating | IK08, IK10 | Measures the enclosure's ability to withstand mechanical impact. | |

| Operating Temperature | -20°C to +60°C (standard), wider ranges available on request | Specifies the permissible ambient temperature range for reliable operation. | |

| Mechanical Life | ≥ 1 x 10^6 operations (momentary), ≥ 0.5 x 10^6 operations (maintained) | Indicates the expected number of mechanical switching cycles the button can withstand. | |

| Cable Entry | Multiple threaded entries (e.g., M20, M25, NPT threads) with certified flameproof cable glands | Allows for secure and flameproof connection of cables. Blanking plugs are used to seal unused entries. | |

| Actuator Type | Momentary push button (flush, raised, mushroom head), selector switch (rotary), key selector switch | Offers different actuation mechanisms for various control requirements. | |

| Actuator Color | Standard colors (e.g., black, red, green, yellow, blue, white) | For easy identification of button functions. | |

| Legend Plate/Marking | Laser-etched or engraved markings for clear identification of functions | Durable and permanent marking suitable for hazardous areas. |

Benefits of Flameproof Push Button Station:

As a flameproof push button station suppliers in India, different benefits are serve for applications and safety environment working purposes as follows.

- Improved Safety:Our basic and only purpose is explosion protection by shielding any internal ignition cause with a housing that significantly reduces the chances of an accident and provides a safe working environment for staff operating in explosive atmospheres.

- Regulatory Compliance: Utilization of certified flameproof equipment provides enhanced levels of safety and regulations compliance to companies in a likely explosive environment, excluding penalties and illegality.

- Operational Reliability: Tough materials and build ensure the stations' resistance to industrial stresses, to provide steady, reliable performance with reduced downtime and maintenance costs.

- Flexible Control Solutions: With varying patterns of button arrangement, selector switches, and indicating lamps, these provide flexible control solution for a wide variety of industrial applications, for various operating requirements.

- Long-Term Cost Savings: Although it could cost more upfront, the reliability, longevity, and prevention of costly accidents incorporated in these stations pay huge dividends in long-term cost savings.

Applications of Flameproof Push Button Station

As flameproof push button station exporters in India, it is applicable in operations and industrial as per requirement which as given below.

- Paint and Coating Plants: Applied on the control of spray booths, mixing equipment, and ventilation systems in working areas where there are combustible paint and solvents.

- Grain Handling and Storage: Applied on the control of conveyors, elevators, and processing equipment where there is a hazard of combustible dust explosion.

- Oil and Gas Industry: Employed extensively in refineries, storage tanks, and drilling rigs for powering pumps, valves, and other machinery where explosive vapors and gas exist.

- Chemical Process Plants: Employed to power reactors, mixers, and transfer pumps when there is flammable solvent and chemical exposure in the surrounding area.

- Mining Operations: Applied on underground equipment, ventilation system, and conveyor operation in mining with potential methane gas and dust explosion hazard.

Pratik Cabletray Pvt. Ltd. is the recommended flameproof push button station manufacturers in India. Flameproof push button stations are the keys to unlocking the achievement of safety and functional performance in environments where there are great risks involved. Our resistance, safety provision, and flexible controls characteristics position them as investments worthy of attention in order to assure the security of individuals, assets, and conformance in many industries. As one of the leading flameproof push button station suppliers in India, and we are proud to be among the trusted flameproof push button station exporters in India, we are committed to delivering not only high-quality products but also responsive service and technical support. Contact us today to request a quote tailored to your specific requirements.

Popular Searches of Flameproof Push Button Station:Flameproof Push Button Station Manufacturers in India, Flameproof Push Button Station Suppliers in India, Flameproof Push Button Station, Flameproof Push Button Station in India, Flameproof Push Button Station India, Top Flameproof Push Button Station Manufacturers in India, Flameproof Push Button Station Exporters in India, Flameproof On Off Push Button, Flameproof Reversed Forward Push Button, Flameproof Weather-proof Push Button Station, Push Button Station, Single Push Button Stations Manufacturers in India, Multi-Push Button Stations Manufacturers in India, Pendant Push Button Stations, Specialized Control Stations, Emergency Stop Stations, Flameproof Indirect Entry Push Button, Flameproof Control Station For Industrial, 10A Flameproof Local Control Station, Clean Room Push Button Station, Top Flameproof Push Button Station Manufacturer in India, Flameproof Push Button Station Manufacturers in India, Flameproof Indirect Entry Push Button Manufacturers in India, Flameproof Switch Socket Manufacturers in India, Flameproof Weatherproof Push Button Station Manufacturers in India, Clean Room Push Button Station in India, Flameproof Push Button Stations Manufacturer from India, Flameproof EOT Crane Pendant Push Button Station in India, Flameproof Industrial Push Button Station in India, Explosion Proof Push Button Station in India, Flameproof On Off Push Button in India, Flameproof On Off Push Button Station in India

Our Products

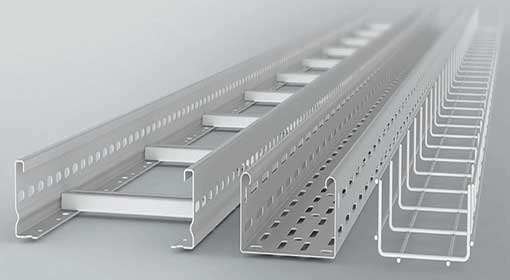

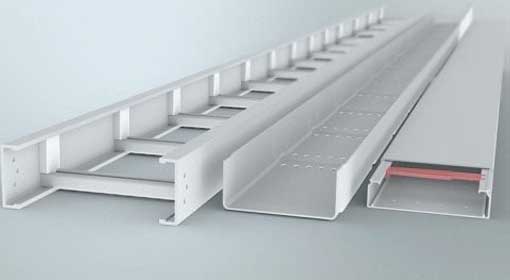

Cable Tray

We have carved a distinct niche in the market owing to the specialized skills, commitments and dedications or our workforce.

Read More

Perforated Type Cable Tray

We have carved a distinct niche in the market owing to the specialized skills, commitments and dedications or our workforce.

Read More

Ladder Type Cable Tray

We have carved a distinct niche in the market owing to the specialized skills, commitments and dedications or our workforce.

Read More

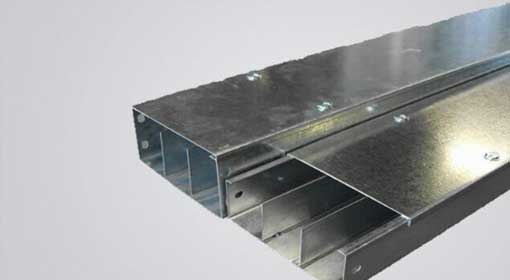

Box Type Cable Tray

We have carved a distinct niche in the market owing to the specialized skills, commitments and dedications or our workforce.

Read More

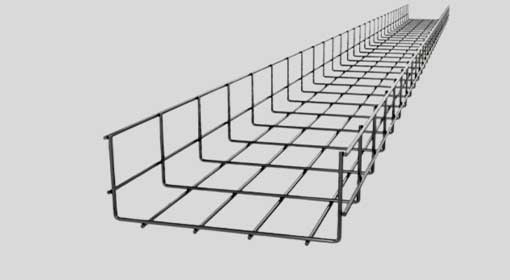

Wire Mesh Cable Tray

We have carved a distinct niche in the market owing to the specialized skills, commitments and dedications or our workforce.

Read More

FRP Cable Tray

We have carved a distinct niche in the market owing to the specialized skills, commitments and dedications or our workforce.

Read MoreFAQs on Flameproof Push Button Station:

Flameproof enclosures are designed to confine any explosion inside the enclosure and avoid transmission to the external explosive environment.

You must decide on hazardous zone classification, control function requirement, environmental conditions, and relevant safety standards.

Although the initial cost will be higher than for standard push buttons, the increased safety and reliability in the long run usually offset the cost.