- Home

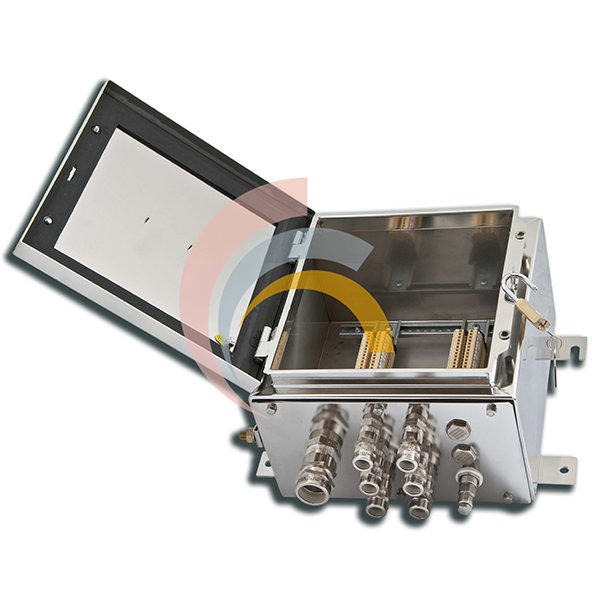

- Flameproof Junction Box in India

Flameproof Junction Box Manufacturers in India|Flameproof Junction Box in India|Flameproof Junction Box Manufacturers 2025

Flameproof Junction Box Manufacturers in India|Flameproof Junction Box Manufacturers, Suppliers, Dealers by Pratik Cabletray Pvt. Ltd.

Related Searches of Flameproof Junction Box Manufacturers: Top Flameproof Junction Box Manufacturers in India, Flameproof Junction Box Suppliers in India, Flameproof Junction Box Exporters in India, Flameproof Junction Box in India, Flameproof On Off Push Button in India, Flameproof Junction Box Suppliers, Flameproof Weather-Proof Junction Box, Aluminium Alloy Flameproof Junction Box Manufacturers, Flameproof Junction Boxes, Flameproof Junction Box India, Flameproof Junction Box Exporters, Stainless Steel Junction Box Flameproof & Weatherproof, Aluminium Junction Boxes Manufacturers in India, Flameproof Junction Boxes Suppliers, Aluminium Flameproof Electrical Junction Box, Fire Flameproof Junction Box, Aluminium Flameproof Junction Box 125mm4 Way Flame Proof Junction Box, Safe Power Flameproof Junction Box, Flameproof Junction Box Manufacturers, Flameproof Junction Box Manufacturers in India, Stainless Steel Flameproof Junction Box Manufacturers in India, Flame proof Junction Boxes Manufacturers in India, Flameproof Weatherproof Junction Box Manufacturers in India, Flameproof Whether Proof Junction Box Manufacturers in India, Aluminium Alloy Flameproof Junction Box in India, Top Flameproof Equipments Manufacturers in India, Popular Flameproof Junction Box Manufacturers in India

Pratik Cabletray Pvt. Ltd. is the leading flameproof junction box manufacturers in India, suppliers and exporters of Flameproof Junction Box in India. It is changing the way cable management is done using green and innovative solutions. Join us as we change the way things are done and bring a progress. We provide customized solutions and industry-leading service to bring success to your project.

Flameproof Junction Box Manufacturers in India

These heavy-duty Flameproof junction boxe suppliers in India are the quiet guardian of safety, providing continuity of operation and protection of lives and assets in applications where one spark would be a disaster. Dive into the flameproof junction boxes' world and learn about our types, primary components, and general applications, and why these represent a vital aspect of industries performing under potentially explosive conditions.

Why to Choose Flameproof Junction Box?

As Flameproof junction box manufacturers in India, we offers a strategic advantage for industries that demand safety, reliability, and cost-efficiency in hazardous environments.

Unbreakable Safety: By creating a solid barrier against the propagation of internal explosions. Regulatory Compliance: Helping to ensure compliance with safety standards of regulation in hazardous settings. Long-Term Reliability: Guarding electrical equipment against hostile environments and damage. Peace of Mind: Guaranteeing warranty of safe and uninterrupted operation in high-hazard industries.

Types of Flameproof Junction Box:

As a Manufacturers, Flameproof junction boxes are categorized by their size, number of ways (connection points), material, and specific design features. Common types include: By Size: like in diameters - 100mm, 150mm, 200mm and shapes - rectangular, circular. By Material: like cast aluminum alloy (LM6), stainless steel, and mild steel. By Design Features: Some boxes have specific features like weatherproof designs, LED-specific designs, and those designed for specific industrial applications.

As a leading flameproof junction box manufacturers, different types are modified as per effectiveness and options which are given below.

- Threaded Enclosures: Threaded fitting for cable and conduit gland entrance is used in these enclosures, which creates a stiff and tight seal that preserves flameproof integrity. Due to its ease and effectiveness, it is one of the standard accepted options.

- Gasketed Enclosures: Machined gaskets and bolt-on covers with precision provide these enclosures with an impenetrable seal against internal emission of explosion. Entrance and size arrangements may be customized.

- Increased Safety (Ex e) Junction Box: Although not always "flameproof," junction boxes are constructed with increased safety features to avoid the generation of sparks, arcs, or elevated temperatures in ordinary service and in certain fault modes, commonly employed in conjunction with flameproof apparatus.

- Terminal Box: Designed to provide terminal blocks for terminal and wiring distribution in hazardous environments, the boxes provide flameproof integrity with space to accept complex wiring patterns.

- Control and Pushbutton Stations: Clustering control devices like pushbuttons, selector switches, and pilot lights into a flameproof enclosure, the assemblies enable safe equipment operation in hazardous environments.

Technical Specification of Flameproof Junction Box:

We have added below a technical sheet of flameproof junction box in India and flameproof junction box suppliers in India, that provides more technical information such as:

| Feature Category | Specification Detail | Common Values/Options | Notes |

|---|---|---|---|

| Hazardous Area Classification | Zone/Division | Zone 0, Zone 1, Zone 2 (Gas); Division 1, Division 2 (Dust & Gas) | Specifies the level of explosion risk the enclosure is designed to withstand. Higher zones/divisions indicate a greater frequency or duration of explosive atmospheres. |

| Gas Group | IIA, IIB, IIC (Gas); IIIA, IIIB, IIIC (Dust) | Categorizes the specific types of flammable gases or dusts the enclosure is certified for. IIC and IIIC represent the most stringent requirements. | |

| Temperature Class | T1 to T6 (e.g., T6: Max Surface Temp 85°C, T1: Max Surface Temp 450°C) | Indicates the maximum surface temperature the enclosure will reach under fault conditions, ensuring it doesn't ignite the surrounding atmosphere. | |

| Ingress Protection (IP) Rating | Solid Particle Protection | IP54, IP65, IP66, IP67, IP68 | Indicates protection against dust and solid objects. Higher numbers offer better protection. |

| Liquid Ingress Protection | IP54, IP65, IP66, IP67, IP68 | Indicates protection against water and other liquids. Higher numbers offer better protection against submersion. | |

| Mechanical Properties | Enclosure Material | Aluminum Alloy (LM6, A356), Stainless Steel (SS304, SS316/L), Carbon Steel with specialized coatings, Glass Fiber Reinforced Polyester (GRP) | Material selection depends on corrosion resistance, mechanical strength, and weight requirements. Stainless steel offers superior corrosion resistance. |

| Impact Resistance (IK Rating) | IK08, IK09, IK10 | Measures the enclosure's ability to withstand mechanical impacts. Higher numbers indicate greater resistance. | |

| Gasket Material | Neoprene, Silicone, Viton, EPDM | Ensures a tight seal to maintain the flameproof integrity and IP rating. Material selection depends on temperature and chemical compatibility. | |

| Lid Fixings | Bolted (multiple), Hinged with locking mechanism | Ensures the lid remains securely closed during an internal explosion. Bolted lids offer higher integrity. Hinged lids provide easier access. | |

| Mounting Options | Surface mount, Pole mount, Wall mount, Pedestal mount | Specifies how the junction box can be installed. | |

| Electrical Properties | Terminal Block Material | Polyamide (PA), Polycarbonate (PC), Ceramic | Provides electrical insulation and secure connections for wires. Ceramic offers high temperature resistance. |

| Terminal Block Configuration | Fixed, Modular, Spring Clamp, Screw Clamp | Affects ease of wiring and vibration resistance. Spring clamp offers faster wiring and better vibration resistance. | |

| Number of Entries/Cable Glands | As per design requirements (specify size and type - e.g., M20, NPT 3/4", Flameproof Cable Glands) | Determines the number and type of cables that can enter the enclosure while maintaining the flameproof integrity. Cable glands must also be appropriately certified. | |

| Earthing/Grounding Provisions | Internal and external earthing studs/terminals | Ensures proper grounding for safety and electromagnetic compatibility. | |

| Safety & Compliance | Certification Body | ATEX, IECEx, UL, CSA, FM (depending on the region and application) | Indicates that the junction box has been tested and certified by a recognized third-party organization for use in hazardous areas. |

| Flameproof Protection Method | "Ex d" (Flameproof Enclosure) | The primary method of protection, where the enclosure is designed to contain an internal explosion and prevent the transmission of the explosion to the surrounding atmosphere. | |

| Marking | Comprehensive marking including certification details, hazardous area classification, temperature class, IP rating, material, etc. | Ensures traceability and proper identification of the enclosure's capabilities and limitations. |

Benefits of Flameproof Junction Box:

Being flameproof junction box suppliers in India, different benefits are provided which are prevent and provide safety which are given below.

- Prevention of External Blasts: Our primary function is to ensure that any internal blast does not escape outside, so that the external fire environment is not ignited, thus protecting people and equipment.

- Continuous Operation Assurance: By protecting vital electrical connections in dangerous explosive environments, these boxes reduce downtime loss due to explosion or fire, resulting in increased productivity and lower operating costs.

- Compliance with Safety Standards: Application of flameproof certified junction boxes is regularly required by industries' safety standards and regulations handling combustible materials for staying within the law and within the safety culture.

- Shielding of Electrical Parts: Flameproof junction box exporters in India' rugged construction protects electrical components from aggressive environment conditions, dust, water, and mechanical shock, hence extending our longevity and reliability.

- Offering Simple Installation Options: Owing to our different sizes, materials, and entry point provisions, flameproof junction boxes may be installed to meet almost any industrial application and installation need.

Applications of Flameproof Junction Box:

As flameproof junction box exporters in India, it is applied in different sites and in facilities services which are given below.

- Oil and Gas Sector: From offshore terminals and storage centers to refineries, these boxes are an answer to keeping electrical equipment from being enclosed in flammable gas- and vapor-containing potentially explosive atmospheres.

- Chemical Processing Plants: Where volatile chemicals are handled and processed in the environment, flameproof junction boxes guarantee the integrity of electrical systems and eliminate the possibility of ignition sources.

- Pharmaceutical Manufacturing: Production of certain drugs includes the use of flammable solvents, for which flameproof enclosures are required to operate electrical equipment safely.

- Mining Operations: Underground mines are full of explosive gases such as methane and hence explosion-proof equipment such as junction boxes needs to be used in order to avoid catastrophic explosions.

- Paint and Coating Facilities: Junction Box Flameproof & Weatherproof Paint and coating storage and application involve explosive solvents and hence flameproof electrical installations need to be utilized to avoid explosion.

Pratik Cabletray Pvt. Ltd. is the recommended flameproof junction box manufacturers in India, Suppliers and Exporters in India. Flameproof junction boxes are not merely electrical fittings; these are safety devices critical to the functioning of safe practices in dangerous industries. Our resistance, range types, and multiplicity of benefits highlight the contribution these make towards avoiding explosions, ensuring continuity of operations, and fulfilling rigorous demands for safety. By offering secure and safe accommodation for electrical connections, these provide safety to lives, equipment, and the environment in applications where ignition hazard is present continuously.

Our Products

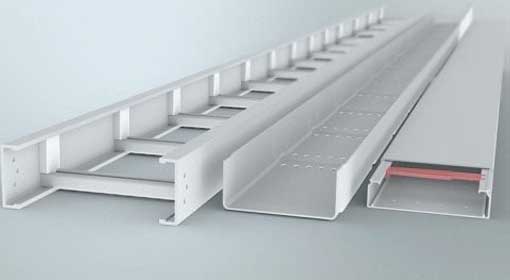

Cable Tray

We have carved a distinct niche in the market owing to the specialized skills, commitments and dedications or our workforce.

Read More

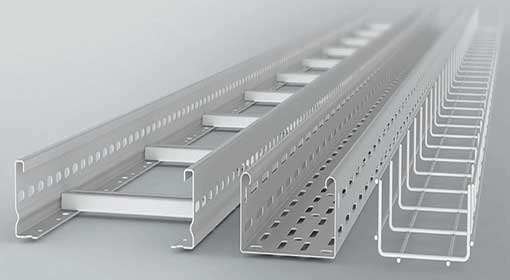

Perforated Type Cable Tray

We have carved a distinct niche in the market owing to the specialized skills, commitments and dedications or our workforce.

Read More

Ladder Type Cable Tray

We have carved a distinct niche in the market owing to the specialized skills, commitments and dedications or our workforce.

Read More

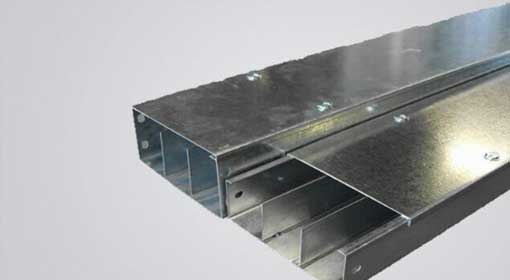

Box Type Cable Tray

We have carved a distinct niche in the market owing to the specialized skills, commitments and dedications or our workforce.

Read More

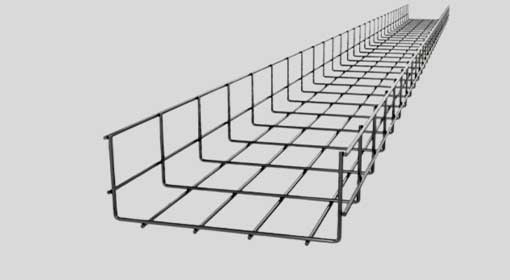

Wire Mesh Cable Tray

We have carved a distinct niche in the market owing to the specialized skills, commitments and dedications or our workforce.

Read More

FRP Cable Tray

We have carved a distinct niche in the market owing to the specialized skills, commitments and dedications or our workforce.

Read MoreFAQs on Flameproof Junction Boxes:

The primary function is to ensure that any explosion within the box is contained so that transmission of hot gases or flames to the outside explosive environment is avoided.

Flameproof junction boxes are tested by reputable test facilities and marked with certain explosion-proof ratings (e.g., Ex d) to reflect compliance with relevant safety standards.

No, standard junction boxes are not explosion-proof and should not be put where there can be explosive atmospheres. Certified flameproof or explosion-proof enclosures alone need to be installed.